2018 Good Quality Waste Medical package Recycling Machine,Medicine Packing Separator

"Sincerity, Innovation, Rigorousness, and Efficiency" would be the persistent conception of our corporation with the long-term to create collectively with buyers for mutual reciprocity and mutual advantage for 2018 Good Quality Waste Medical package Recycling Machine,Medicine Packing Separator, We have expanded our business into Germany, Turkey, Canada, U. S. A. , Indonesia, India, Nigeria, Brazil and some other regions of the world. We are working hard to be one of the best global suppliers.

"Sincerity, Innovation, Rigorousness, and Efficiency" would be the persistent conception of our corporation with the long-term to create collectively with buyers for mutual reciprocity and mutual advantage for Aluminium/plastic Recycling Machine, Voltage Electrostatic Separation, Waste Medical package Recycling Machine, Our merchandise are mainly exported to Europe, Africa, America, the Middle East and Southeast Asia and other countries and regions. We've enjoyed a great reputation among our customers for quality solutions and good services.We would make friends with businessmen from at home and abroad, following the purpose of "Quality First, Reputation First, the Best Services."

Medical aluminium plastic package separating equipment

Scope of application:

It is suitable to the physical separation of aluminum and plastics package of food, tablet aluminum-plastic packaging materials, aluminum-plastic scraps and all kinds of aluminum-plastic composite materials.

Structural feature:

- PLC automatic control with manual operating screen , make sure the material evenly feeding during entire production line.

- Compact structure, reasonable layout, stable performance, Low noise.

- The crushing and grinding process equipped with a circulating water cooling machine, which avoid the plastic melting or discoloring because of the high temperature after long operation of the equipment.

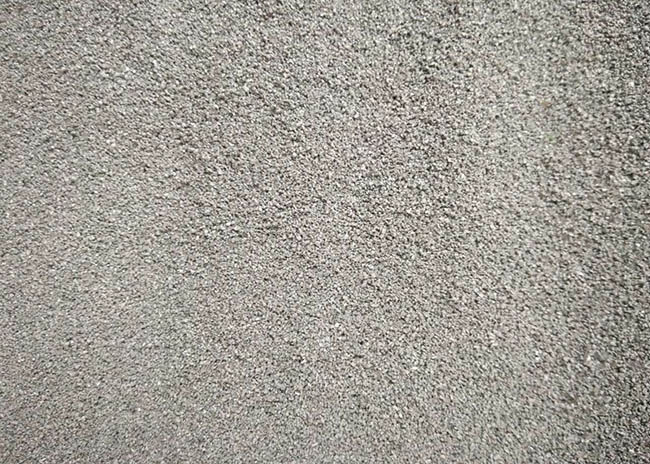

- Physical crushing, grinding and electrostatic separation method to sort the aluminum and plastic. It is environmentally and friendly separation method which replaced the original chemical pharmacy aluminum-plastic separation.

- The entire production line is equipped with pulse dust collector, thus purifying the work space.

- The highest separating rate of aluminum and plastic can reach more than 99.9%.

- Equipment can be customized according to customers' capacity requirement.

+

+ +

+ +

+ +

+ +

+