China Cheap price Plastic Hdpe Recycling Equipment - Motor Rotor recycling equipment – Suyuan Lanning

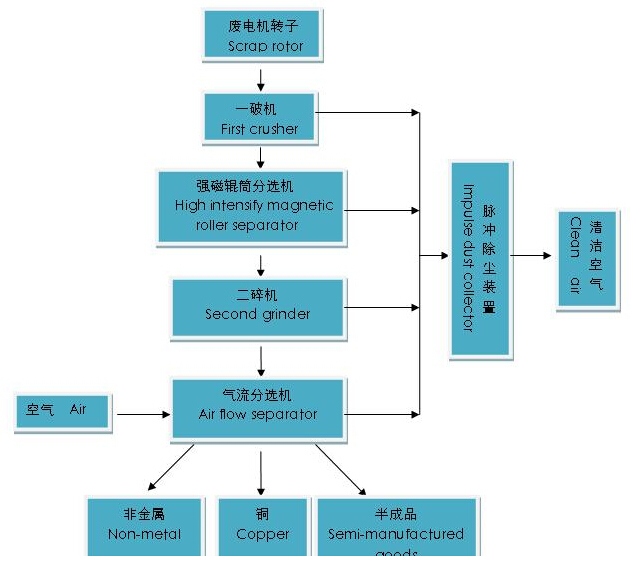

JZ-ZZ1500 Scrap rotor recycling prodution line:

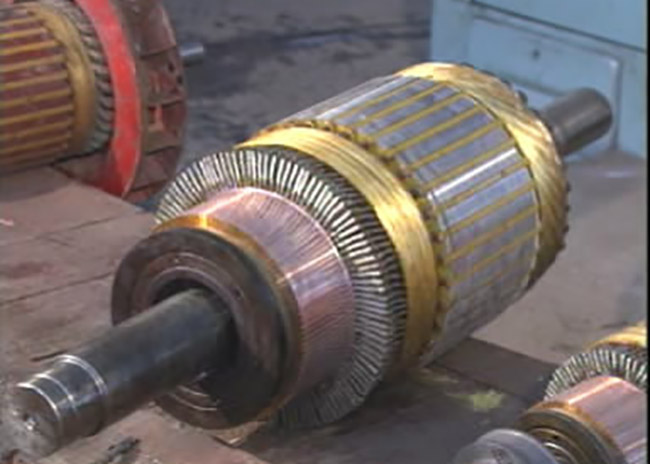

Scrap rotor harmless treatment and recycling machine, which adopts dry-type grinder and magnetic separator to break and separate the rotor, turn the rotor into copper and iron. The whole process is conducted in negative pressure.

Axis, bearing, gear, big hard iron block are prohibited to feed to the machine. The rotors are transported to crusher by conveyor, then to magnetic roller separator to get color metal and iron. The copper mixture is transferred to grinder, then through air separator to get copper and non-metal. Pulse dust catcher system is allocated in grinder and separation part.

Craft diagram:

Parameters:

|

Dimension(MM) |

Output(T/H) |

Separation Rate |

Dust-cleaning Rate |

Power(KW) |

|

15200×5800×5000 |

1.5 |

>98% |

>99% |

132.85 |

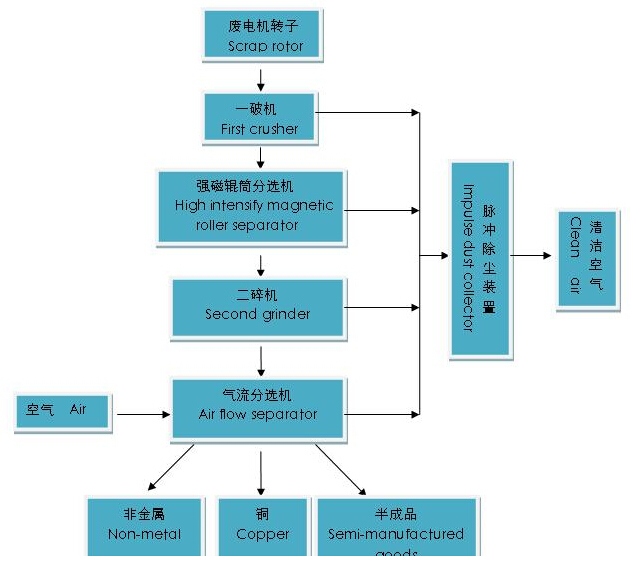

JZ-ZZ930 Scrap rotor recycling prodution line:

physical way to recycle the equipment, controlled by PLC. The manually selected stators, coils are transported to first crusher, second grinder, then through manetic roller to separate toiron and copper. The copper mixture are transferred to grinder to get smaller production, then to air separator to get purifier copper granular. The machine can reach a considerable economic benefits. The dust caused by crush and separation will catched by pulse dust catch system, which will prevent the environment from dusts pollution.

Scrap rotor harmless treatment and recycling machine, which adopts dry-type grinder and magnetic separator to break and separate the rotor, turn the rotor into copper and iron. The whole process is conducted in negative pressure.

Axis, bearing, gear, big hard iron block are prohibited to feed to the machine. The rotors are transported to crusher by conveyor, then to magnetic roller separator to get color metal and iron. The copper mixture is transferred to grinder, then through air separator to get copper and non-metal. Pulse dust catcher system is allocated in grinder and separation part.

Craft diagram:

Parameters:

|

Dimension(MM) |

Feeding(MM) |

Output(T/H) |

Separation Rate |

Dust-cleaning Rate |

Power(KW) |

|

13900×5500×5000 |

<1000 |

0.8-1.2 |

>98% |

>99% |

112.85 |

-

Factory Free sample Metal Free Rubber Recycling...

-

Hot-selling wire crushing recycling machine - ...

-

Top Suppliers Film Washing Recycling Machine -...

-

China OEM Cable Wire Stripper Machine - Electr...

-

Factory Supply Lead Acid Battery Recycling Equi...

-

Popular Design for Cable Crimping Machine - Pl...

+

+ +

+ +

+ +

+ +

+ +

+