Good quality Ldpe Recycling Machine - Manufactur standard Weee Electronic Waste Scrap Computer Pcb Circuit Board Recycling Equipment – Suyuan Lanning

Which has a positive and progressive attitude to customer's fascination, our company repeatedly improves our products quality to meet the desires of consumers and further focuses on safety, reliability, environmental requirements, and innovation of Manufactur standard Weee Electronic Waste Scrap Computer Pcb Circuit Board Recycling Equipment, Therefore, we can meet different inquiries from different consumers. You should find our web page to check additional info from our products.

Which has a positive and progressive attitude to customer's fascination, our company repeatedly improves our products quality to meet the desires of consumers and further focuses on safety, reliability, environmental requirements, and innovation of Electronic Circuit Board Recycling Equipment, Scrap Computer Circuit Board Recycling Equipment, Scrap Pcb Circuit Board Recycling Equipment, Welcome to visit our company, factory and our showroom where displays various hair products that will meet your expectation. Meanwhile, it is convenient to visit our website, and our sales staff will try their best to provide you the best service. Please contact us if you need more information. Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation.

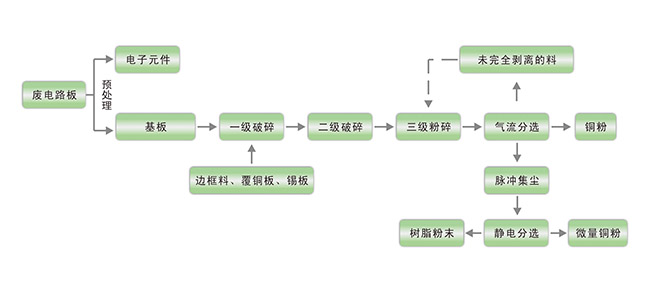

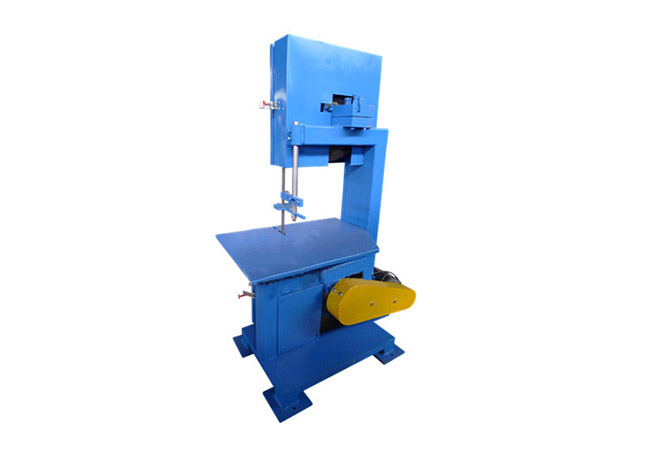

Circuit board recycling equipment

Scope of application:

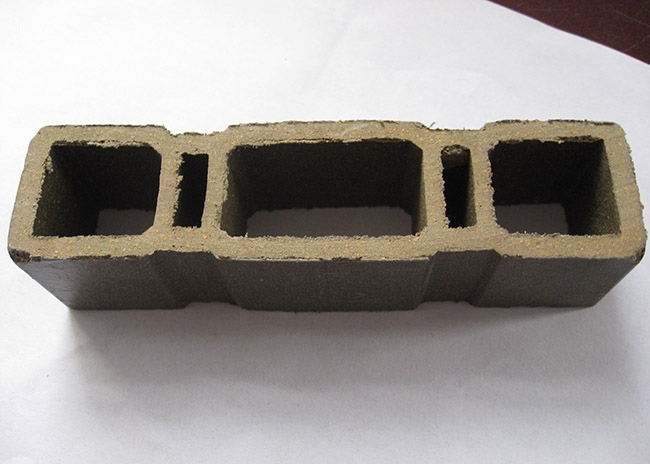

It is used for separating metals and non-metals in materials, such as waste circuit boards, CCL, circuit boards, bits and pieces, and recovering metals and resin powder in those materials.

Features of equipment:

1. The entire assembly line uses the PLC intelligent programming automatic control and man-machine interface touch screen, so that the even feeding of the entire production line and coordinated work can be realized.

2. Compact structure, reasonable layout, stable performance, noise reduction treatment of the crushing equipment.

3. The crushing part uses shredding, smashing and crushing processes, and circulating water cooling is used inside and outside the crushing chamber.

4. Use the negative pressure feeding system and pulse dust removal system to purify the working environment.

5. The sorting part adopts the proportion sorting combined with the static careful selection, so that the metal recovery rate can reach up to more than 99%.

-

OEM China Manufacturer Metal Shredder - Radiat...

-

OEM Customized Desktop-Type Cable Stripper Mach...

-

Factory Free sample Tire Repair Tools - Tire s...

-

Big discounting Tire Fuel - Electrostatic sepa...

-

Popular Design for Cable Crimping Machine - Dr...

-

New Delivery for Oil Recycling - Tire strip cu...

+

+ +

+ +

+ +

+