1.Bahan Mentahan Mesin Pirolisis

| NO. | jeneng | Foto |

| 1 | Akeh Jinis Sampah Plastik PE> 70%, PVC <20%. Luwih PE, Tingkat Ngasilake Minyak Luwih |

|

| 2 | Sampah Ban |

|

| 3 | Sampah Karet |  |

| 4 | Sampah Kulit Kabel |

|

| 5 | Tlapak sepatu sampah |  |

| 6 | Akeh jinis sludge lenga |  |

| 7 | Akrilik sampah |

|

| 8 | Limbah kulit |  |

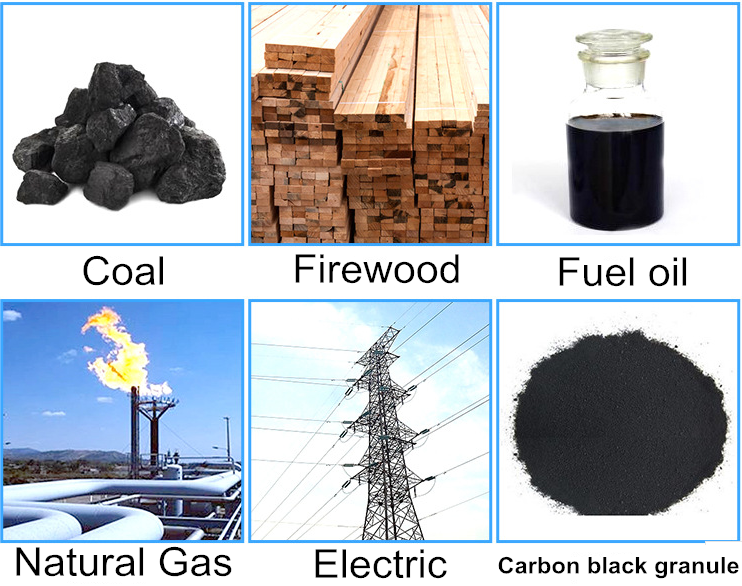

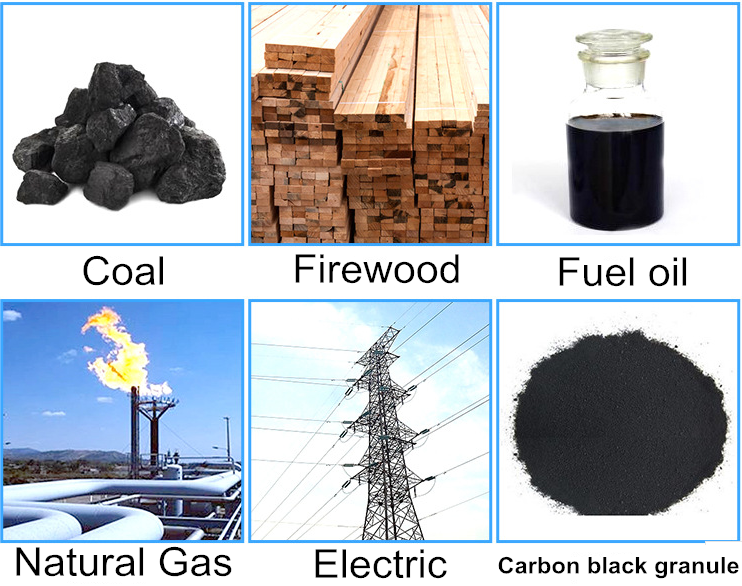

2.Bahan Bakar Mesin Bisa Gunakake

| NO. | 1 | 2 | 3 | 4 | 5 | 6 |

| Bahan bakar | Batu bara | Kayu bakar | Lenga (BBM/Ban/ lenga abot lsp) | Gas alam | Listrik | Karbon ireng pelet |

| Cathetan | / | / | Pembakar lenga abot | Pembakar gas alam | Sistem pemanas listrik | Miturut mesin pelet ireng karbon |

3.Rate produk pungkasan lan panggunaan

| Bahan Baku | Tingkat produk pungkasan |

| Minyak Tungku | Karbon ireng | baja | Limbah Gas |

| Sampah ban/karet | Ban truk | 45%--50% | 25%-30% | 10% | 10%-15% |

| Ban mobil | 40%-45% | 30%-35% | 10% | 10%-15% |

| Sepeda lan ban motor | 30%--35% | 35%-40% | 10% | 15%-25% |

| Sampah plastik | Jaring iwak, Safety net, film farm-oriented | 45%--50% | 30%-40% | | 15%-25% |

| Tas sing trep, tas anyaman | 40% | 40% | | 20% |

| Cut saka pabrik kertas daur ulang | 20%--30% | 45%-55% | | 25% |

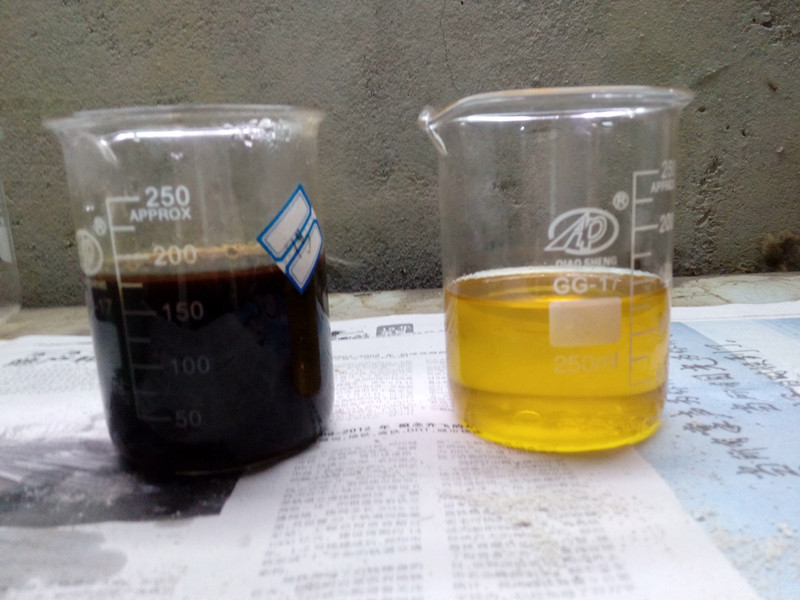

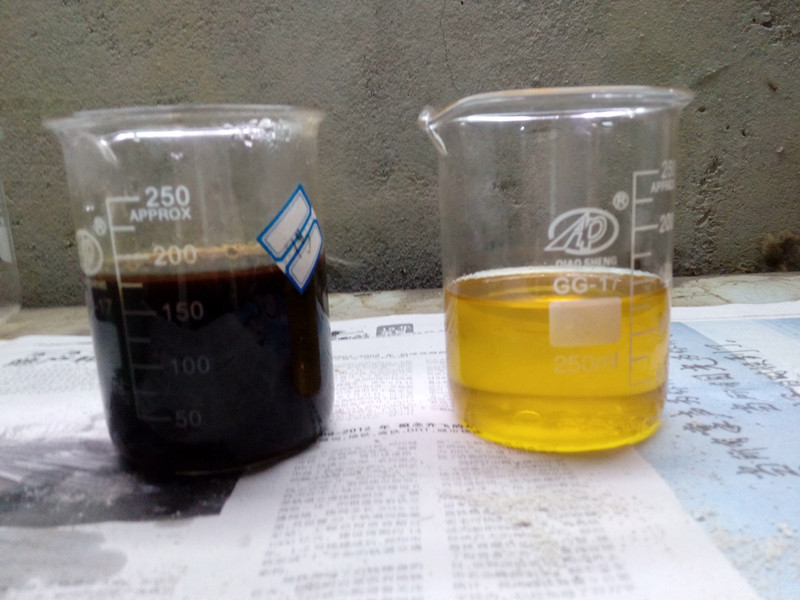

| No | Produk pungkasan | Panggunaan | Gambar |

| 1 | Oli ban | * Didol.* Distillating kanggo Diesel lan Bensin.* Digunakake minangka bahan bakar. |  |

| 2 | karbon ireng | * For sale.* Refine to Fine carbon black.* Ngasilake Carbon Black Pellet |  |

| 3 | Limbah kawat baja | *Didol.*Packing kanggo blok baja kanggo transportasi lan panyimpenan gampang. |  |

| 4 | lenga gas | * Minangka bahan bakar * Gas exhaust sing berlebihan bisa disimpen ing sistem panyimpenan. | |

5.Model Lan Kapasitas

| NO. | Model | Ukuran reaktor | Kapasitas | Cathetan |

| 1 | ST-2200*6000 | 2200 * 6000 mm | 5-6 Ton/batch | 2 dina 3 klompok |

| 2 | ST-2200*6600 | 2200 * 6600 mm |

| 3 | ST-2400*6000 | 2400 * 6000 mm | 6-7 Ton/batch | 2 dina 3 klompok |

| 4 | ST-2400*6600 | 2400 * 6600 mm |

| 5 | ST-2600*6000 | 2600 * 6000 mm | 8-10Ton / batch | 1 dina 1 batch |

| 6 | ST-2600*6600 | 2600 * 6600 mm |

| 7 | ST-2800*6000 | 2800 * 6000 mm | 10 Ton/Batch | 1 dina 1 batch |

| 8 | ST-2800*6600 | 2800 * 6600 mm | 12 Ton/batch | 1 dina 1 batch |

| 9 | ST-2800*8100 | 2800 * 8100 mm | 15 Ton/Batch | 1 dina 1 batch |

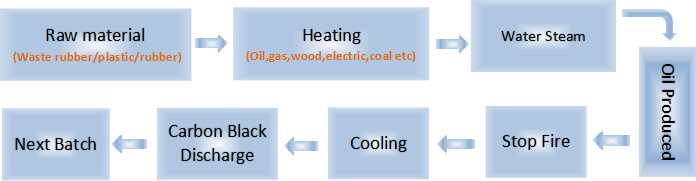

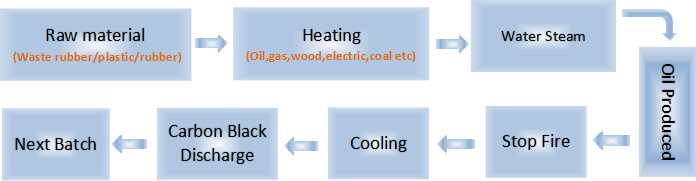

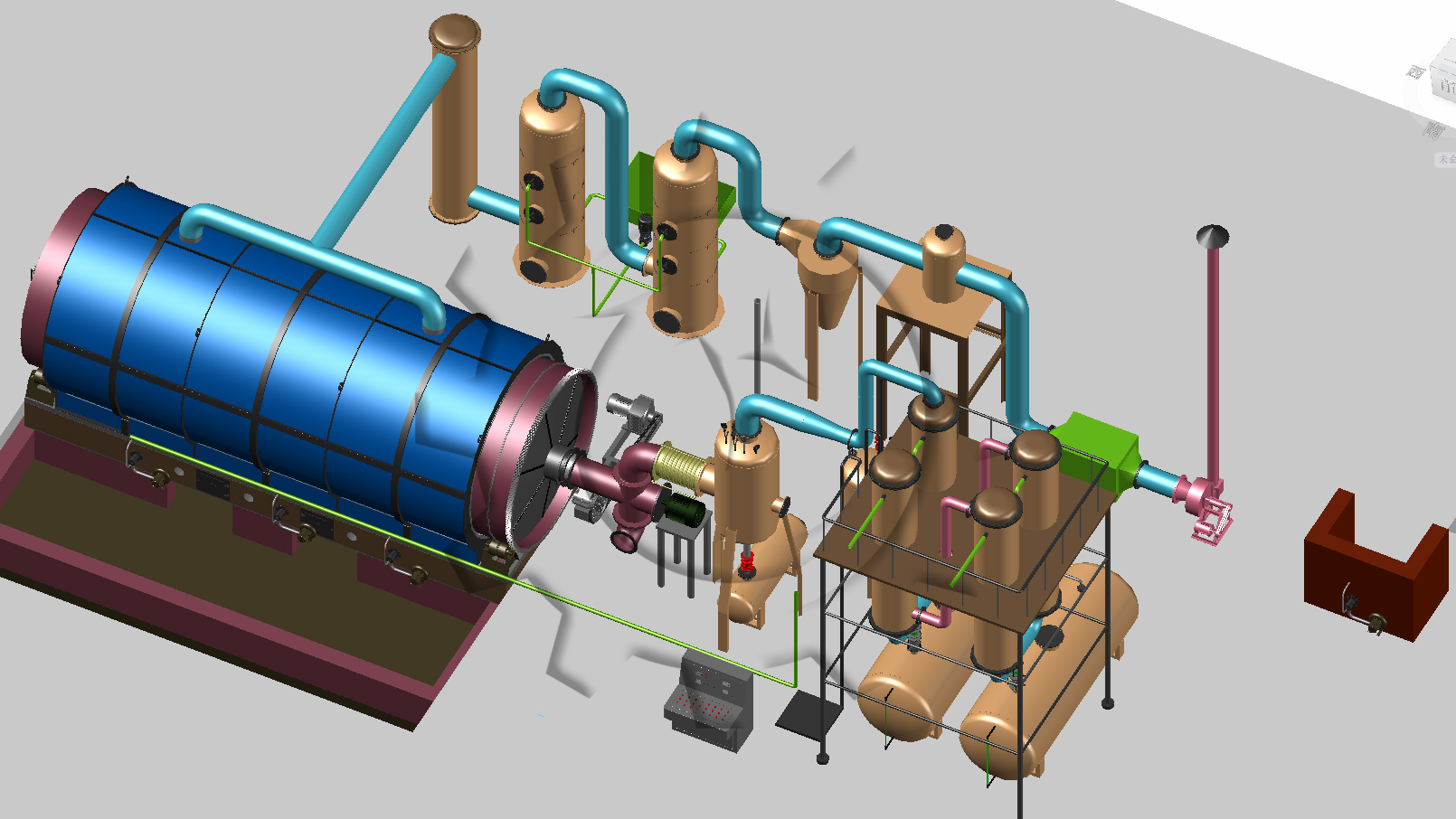

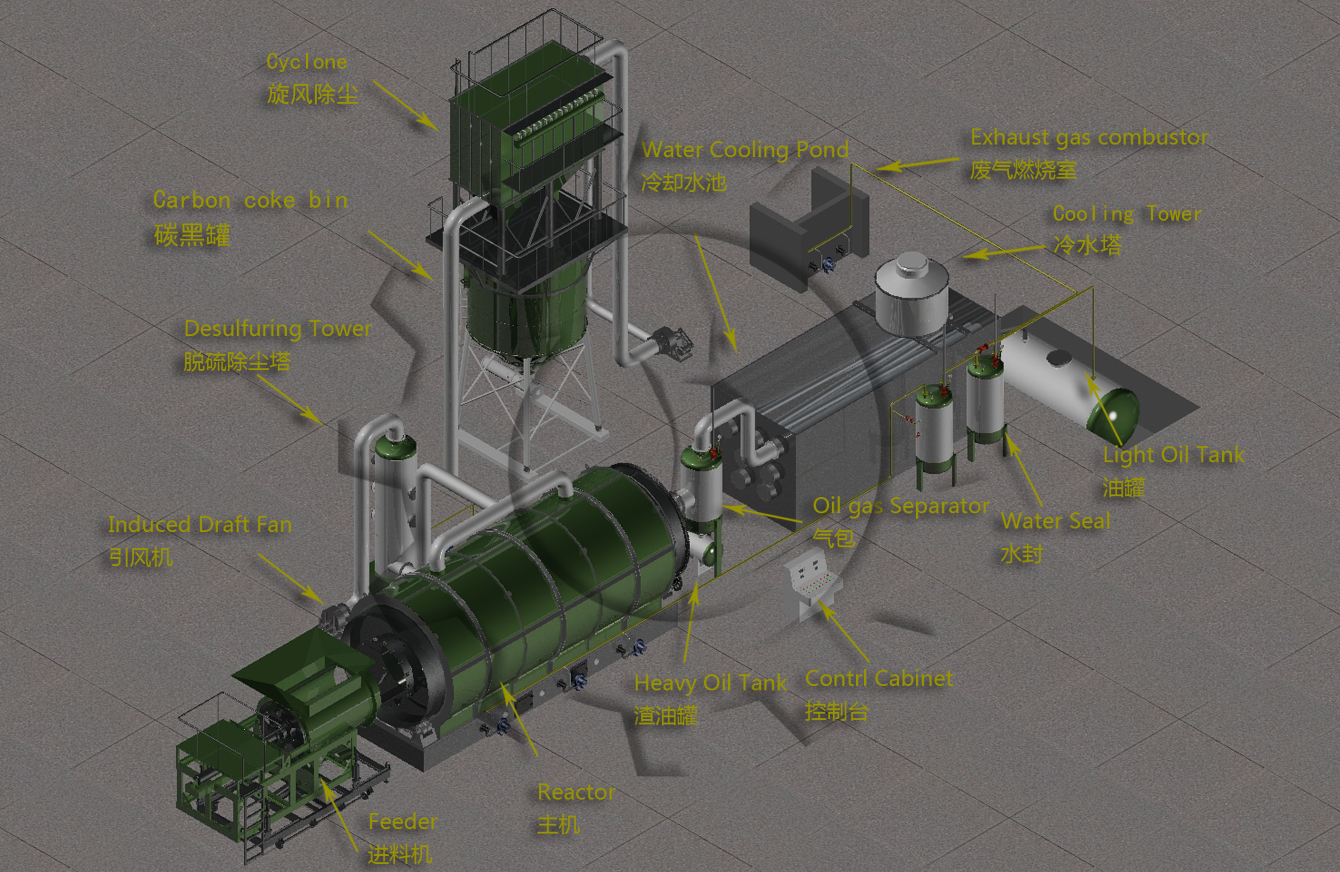

6. Prinsip Kerja

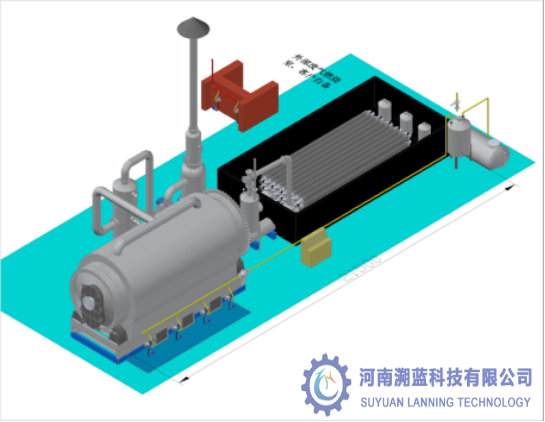

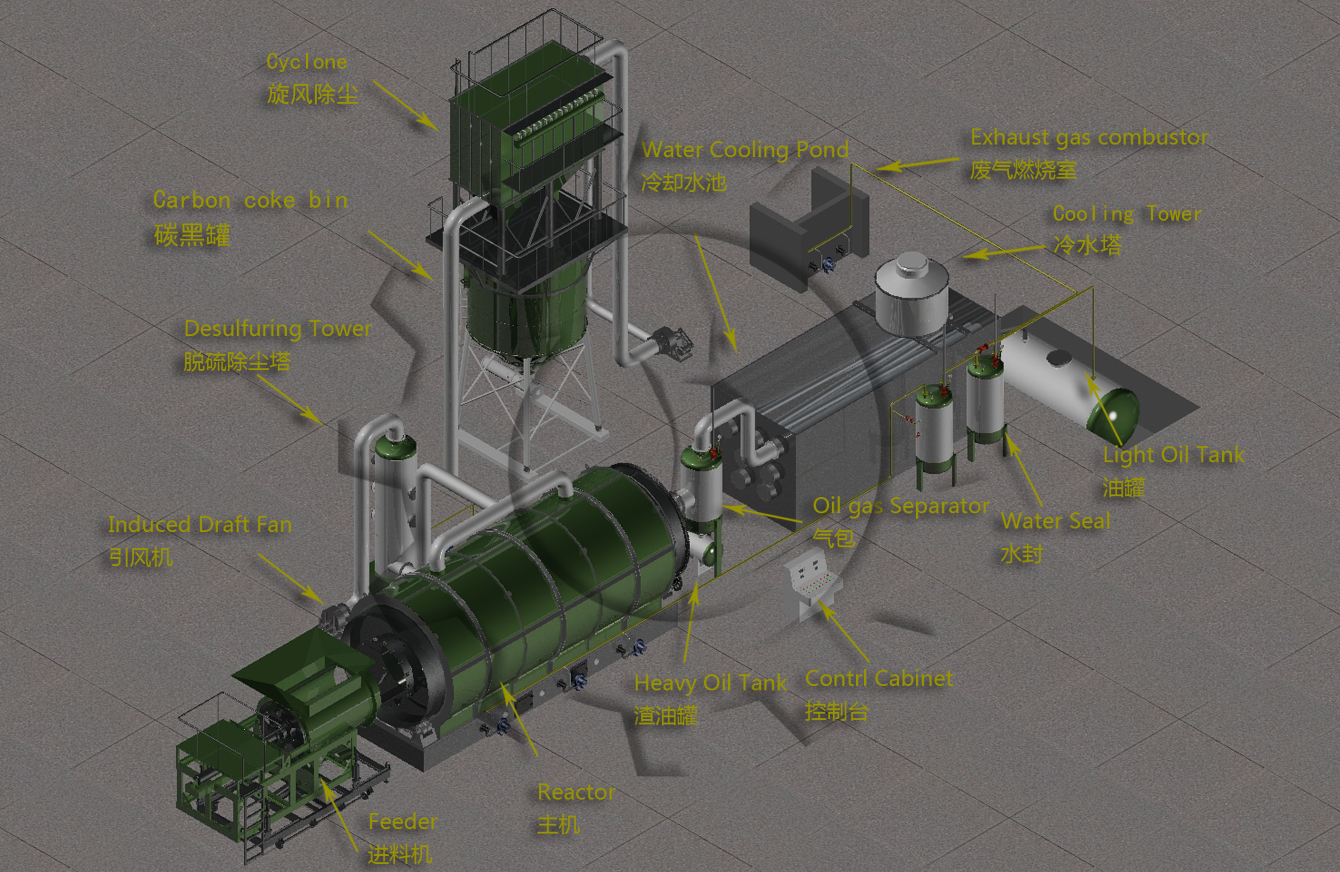

7. Konfigurasi 5-15ton

Mangga wenehi pitakonan ing ngisor iki:

(1) Apa bahan baku sampeyan?

(2) Apa kapasitas (Ton saben dina) sampeyan pengin?

(3) Apa sumber panas sampeyan?Minyak, gas, batu bara?

(4) Cara discharge: Discharge ngarep utawa discharge mburi?

(5) Cara cooling: cooling blumbang banyu utawa cooling condenser?

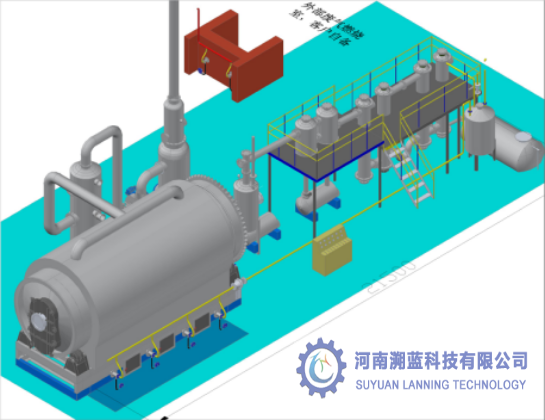

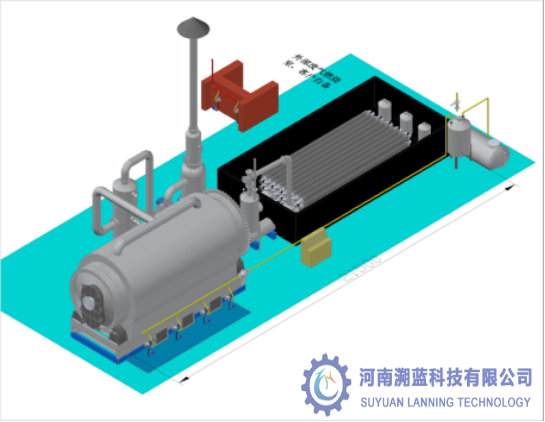

(1)Pabrik Pirolisis KanthiSistem Pendingin Kolam Air/ Discharge ngarep

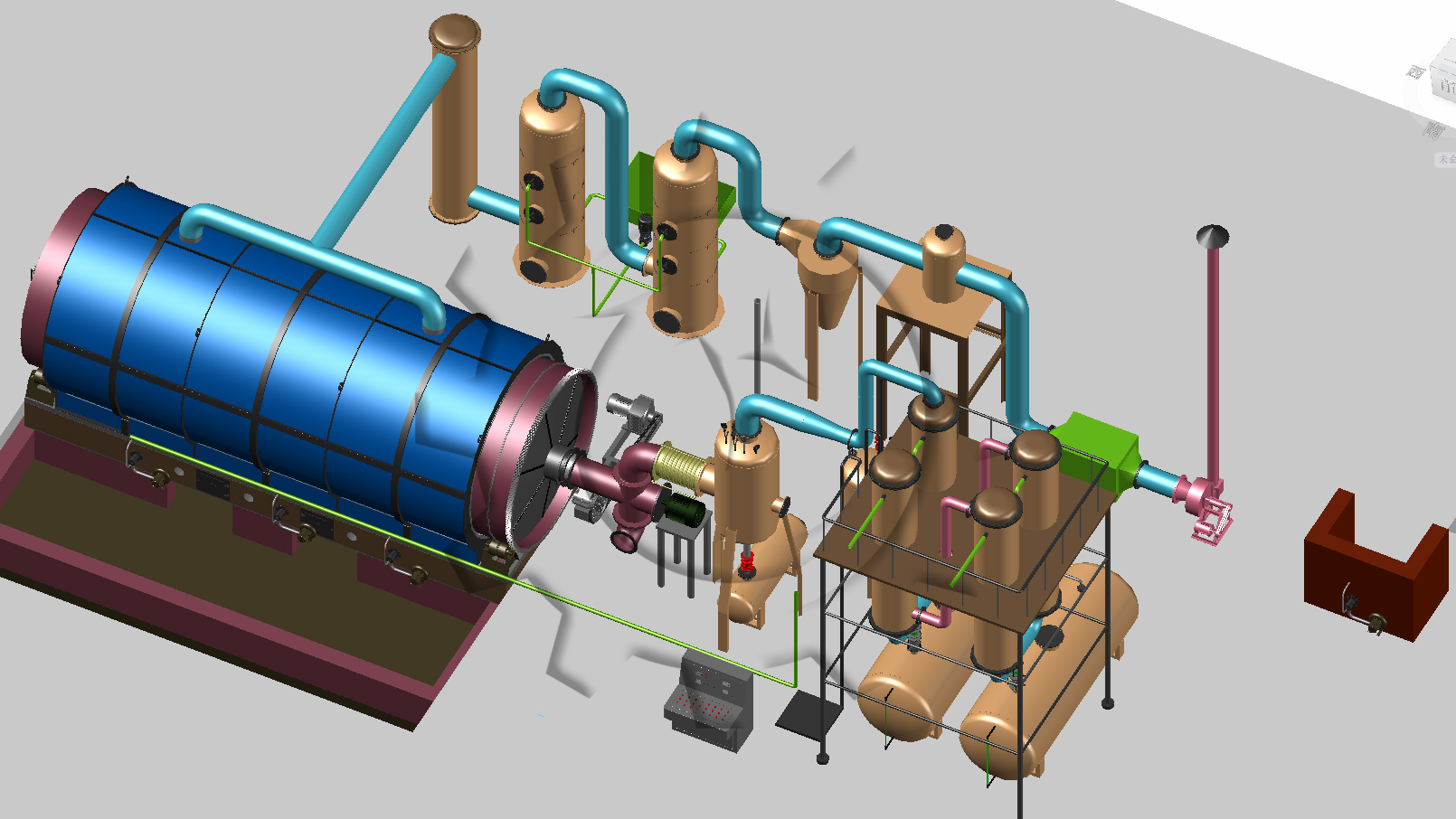

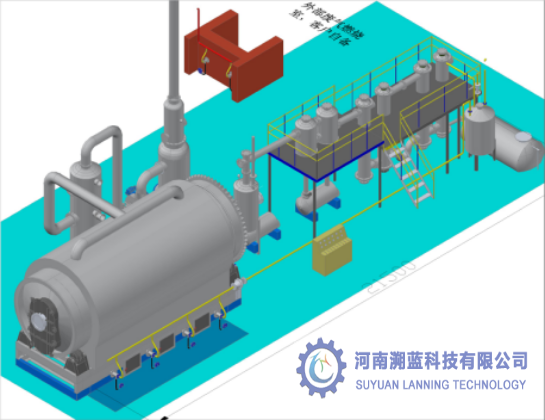

(2)Pabrik Pirolisis kanthi sistem pendingin kondensor Vertikal / Discharge ngarep

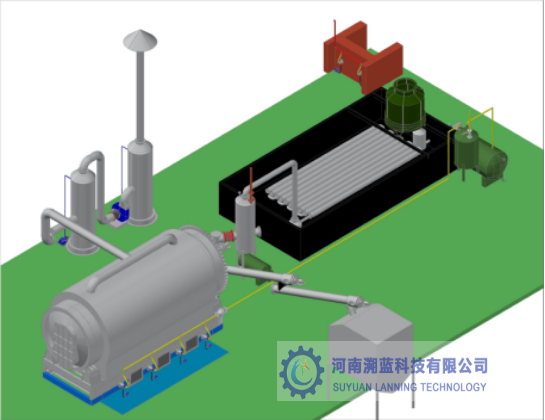

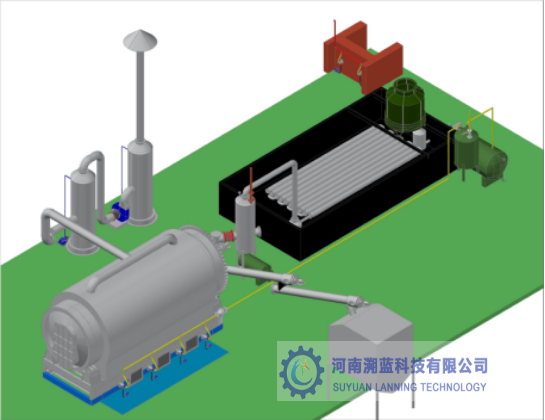

(3)Pabrik Pyrolysis karoSistem Pendingin Kolam Air/ Discharge mburi

(4) Pabrik Pirolisis kanthi sistem pendinginan kondensor / discharge mburi

(5)Pabrik Pirolisis karoSistem Pendingin Kolam Air/Mburi sistem discharging tekanan negatif

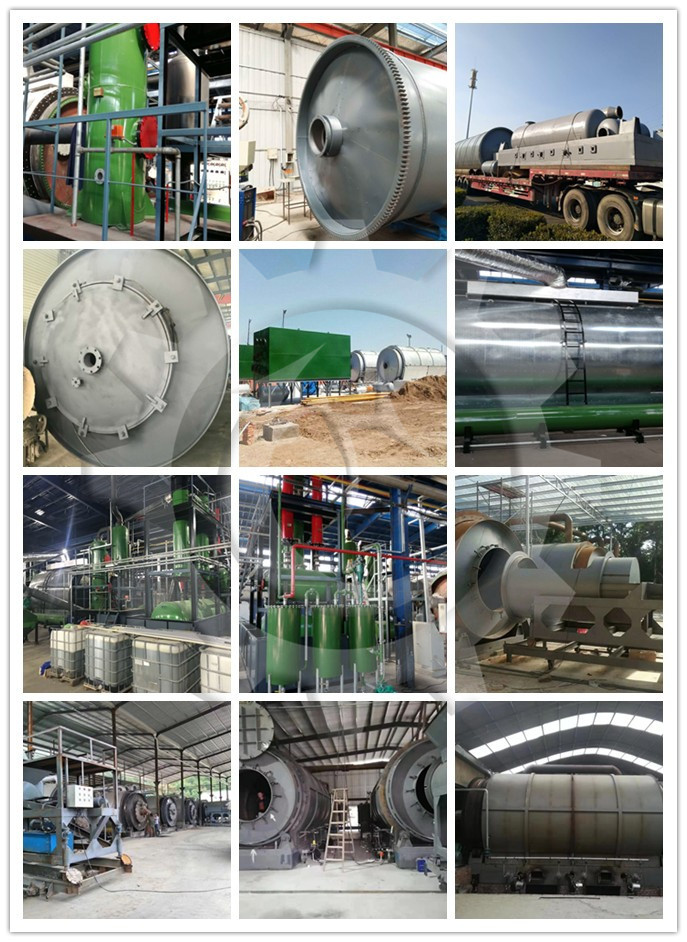

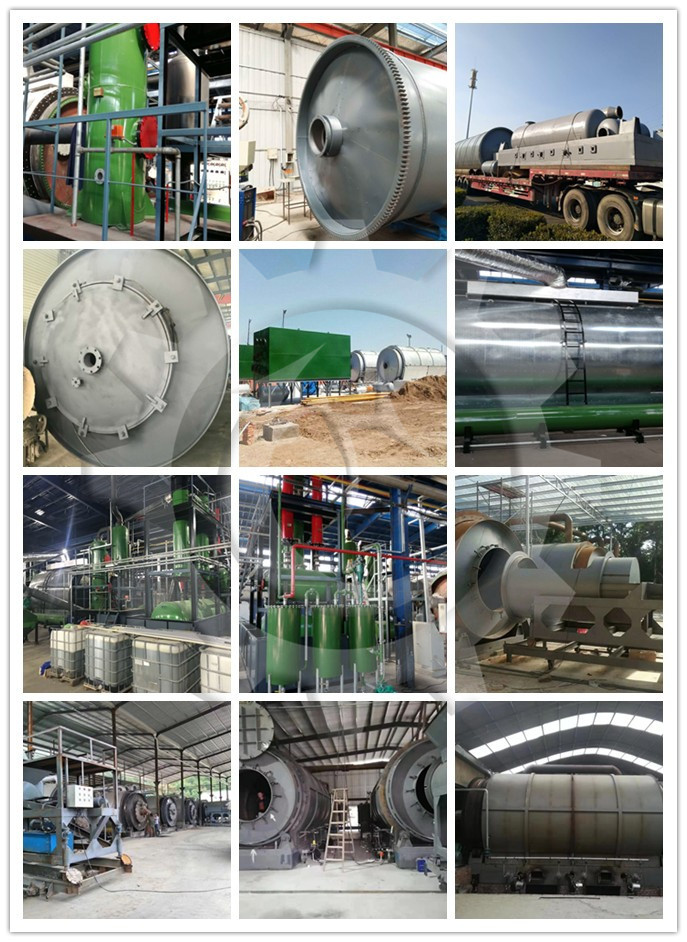

8.Gambar

(1) Rincian

(2) Pangiriman

(3) Lapangan kerja

+

+ +

+ +

+ +

+ +

+ +

+