Low price for Rg59 Stripper - Personlized Products Used Electric Motor Cutting Cable Machine Bs-040 Scrap Copper Recycle – Suyuan Lanning

Our advantages are lessen charges,dynamic income team,specialized QC,sturdy factories,premium quality services for Personlized Products Used Electric Motor Cutting Cable Machine Bs-040 Scrap Copper Recycle, High quality, timely services and Aggressive selling price, all acquire us a superior fame in xxx field despite the international intense competition.

Our advantages are lessen charges,dynamic income team,specialized QC,sturdy factories,premium quality services for Copper Wire Recycling Machine, Recycling Machine For Copper, Waste Copper Wire Peeling Machine, We've been proud to supply our products and solutions to every auto fan all around the world with our flexible, fast efficient services and strictest quality control standard which has always approved and praised by customers.

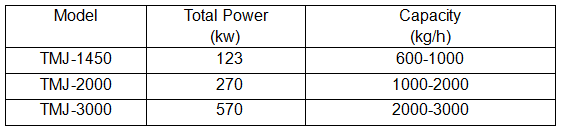

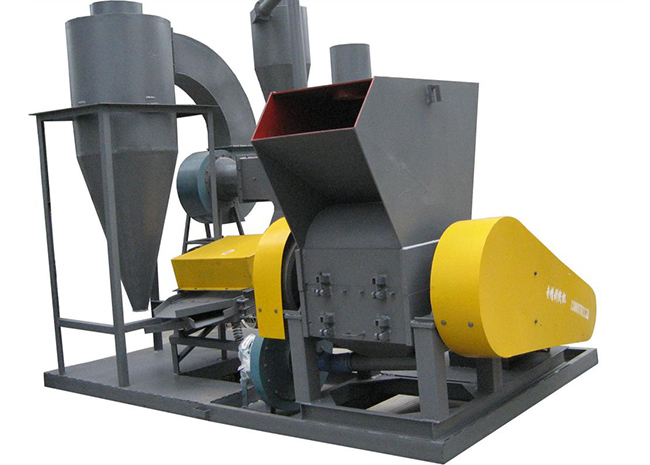

TMJ Cable Granulator Line

Throughout the world, there are varies kinds of waste cables, our aim is to overcome the loss of copper and other metals during processing for regeneration, to make it more scientific, automation. It reduces labors, increase the recovery rate, and therefore improve production efficiency. The whole production line is designed to be scientific, environmentally friendly, and cost-effective.

Mayslynn Recycling Company developed first Cable Granulator recycling line in China in 1996. In the past 20 years, with continuous innovation and optimization, we have been always maintain the industry-leading level, and position as benchmark within the industry in China. We have been installed more than 500 sets of Cable Granulator around the world, which shows high degree of customer recognition.

TMJ model Cable Granulator line can recycle the waste cables by crushing, gravity separation, vibration separation, magnetic separation processes to separate the plastic and copper, iron, etc… the recovery rate is up to 99%.

Advantages:

1.Intelligent control with reasonable layout, automatic shutdown protection during overload operation.

2.Can be equipped with shredder as first crusher, auxiliary mechanized feeding, which reduce labor cost.

3. With high-precision sorting system and frequency control, the recovery rate can be as high as 99%.

4. Crushing system using high-strength alternating blade shaft with high crushing efficiency, the blade material is alloy steel.

5. Crusher is equipped with cooling system, to prevent the plastic from sticking copper when the temperature is getting too high.

6. he equipment is operating closed with additional dust removal system, with effective control of dust, environmental friendly.

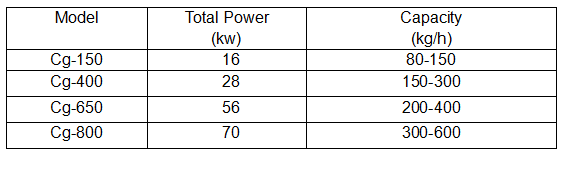

CG Cable granulator

Throughout the world, there are varies kinds of waste cables, our aim is to overcome the loss of copper and other metals during processing for regeneration, to make it more scientific, automation. It reduces labors, increase the recovery rate, and therefore improve production efficiency. The whole production line is designed to be scientific, environmentally friendly, and cost-effective.

Mayslynn Recycling Company developed first Cable Granulator recycling line in China in 1996. In the past 20 years, with continuous innovation and optimization, we have been always maintain the industry-leading level, and position as benchmark within the industry in China. We have been installed more than 500 sets of Cable Granulator around the world, which shows high degree of customer recognition.

Advantages:

1. The equipment is modular with compact structure and an occupation of smaller area.

2. Excellent in shape, safe and stable, easy to operate, no complicated installation and only one operator can operate after being electrified.

3. Sorting system: high-precision sorting with frequency control applied. The sorting rate is up to 99%.

4. Crushing system: the high-intensity staggered blades has a higher crushing efficiency. The blade is made of alloy steel with durable long life.

5. The equipment is operating closed to avoid the loss of material, the dust emissions with the additional bag filter and air filter system to effectively control the dust.

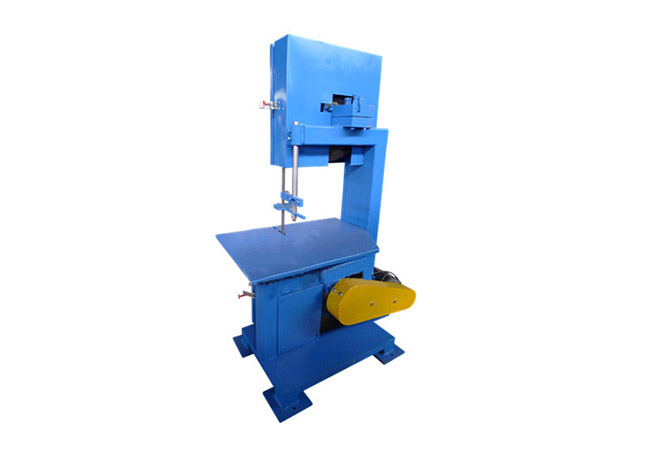

Dry-type copper recycling production line:

The environment of the production line should be dry and clean. Several shearing and crushing process are approached to separate the materials. The machine set peels off the household scrap cable wires of the plastic sheath and the copper, separating them into the plastic fragment and copper powder. The whole waste copper recycling production line is controlled by PLC (Programmable Logic Controller) except the manual material feeding. It has the automatic functions of overload warning and blockage shut-down. It is easy and safe to operate.

Features:

1.Compact structure and reasonable layout, easy to install.

- 2.Controlled by PLC. Continuous feed, intelligent operation, easy to operate.

- 3.The structure of the machine is easy for move and transportation.

- 4.The second grinder adopts alternate blades leading to high productivity, low noise and stable running.

- 5.The separator rate for communication wire can reach up to 97%, mixed wire reach up to 95%.

- 6.The semi-material processing for two times which separate the metal and non-metal total.

- 7.No dust outlet, the dust separation rate can reach up to 99%.

Display:

|

Model |

Power(KW) |

Output(T/H) |

Separation Rate |

Dust-cleaning Rate |

Dimension(MM) |

|

JZ-DX500 |

71.99 |

0.5 |

95%-99% |

99% |

7670MM×7000MM×3200MM |

|

JZ-DX800 |

92.62 |

0.6-0.8 |

95%-99% |

99% |

8000x5200x3300 |

|

JZ-DX1000 |

120 |

1.0 |

>97% |

99% |

7500×4800×3400 |

|

JZ-DX1200 |

165 |

1.0-1.2 |

>99% |

99% |

12600×6350×4000 |

|

JZ-DX1500 |

175 |

1.2-1.5 |

>95% |

99% |

21700×4500×5000 |

Parameters:

|

Model |

Power(KW) |

Output(T/H) |

Separation Rate |

Dust-cleaning Rate |

Dimension(MM) |

|

JZ-DX500 |

71.99 |

0.5 |

95%-99% |

99% |

7670MM×7000MM×3200MM |

|

JZ-DX800 |

92.62 |

0.6-0.8 |

95%-99% |

99% |

8000x5200x3300 |

|

JZ-DX1000 |

120 |

1.0 |

>97% |

99% |

7500×4800×3400 |

|

JZ-DX1200 |

165 |

1.0-1.2 |

>99% |

99% |

12600×6350×4000 |

|

JZ-DX1500 |

175 |

1.2-1.5 |

>95% |

99% |

21700×4500×5000 |

JZ-DX4000:The capacity of the standard production line is 2000kg/h to 4000kg/h. Also the big type can according to the customer’s requirements to design it. (Like 6T/H, 8T/H, 10T/H)

-

Reasonable price Plastic Scrap Crusher - 8 Yea...

-

Cheap PriceList for Electric Wire Stripping Mac...

-

China Cheap price Pyrolysis Oil To Diesel Equip...

-

Free sample for Mechanical Wire Stripping Tool ...

-

Factory source Fine Crusher Sand Washer - Whol...

-

Wholesale Coaxial Cable Cutter - Tire Sidewall...

+

+ +

+ +

+ +

+ +

+