Manufactur standard Waste Recycling Equipment - China New Product Auto Alu-alu Alu-pvc Waste Medical Blister Recycling Machine – Suyuan Lanning

We thinks what buyers think, the urgency of urgency to act during the interests of a purchaser position of theory, allowing for much better high-quality, reduced processing costs, charges are more reasonable, won the new and outdated consumers the support and affirmation for China New Product Auto Alu-alu Alu-pvc Waste Medical Blister Recycling Machine, We are devoted to provide professional purification technology and solutions for you!

We thinks what buyers think, the urgency of urgency to act during the interests of a purchaser position of theory, allowing for much better high-quality, reduced processing costs, charges are more reasonable, won the new and outdated consumers the support and affirmation for Auto Alu-alu Waste Medical Blister Recycling Machine, Auto Alu-pvc Waste Medical Blister Recycling Machine, Waste Medical Blister Recycling Machine, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade items in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market.

Medical aluminium plastic package separating equipment

Scope of application:

It is suitable to the physical separation of aluminum and plastics package of food, tablet aluminum-plastic packaging materials, aluminum-plastic scraps and all kinds of aluminum-plastic composite materials.

Structural feature:

- PLC automatic control with manual operating screen , make sure the material evenly feeding during entire production line.

- Compact structure, reasonable layout, stable performance, Low noise.

- The crushing and grinding process equipped with a circulating water cooling machine, which avoid the plastic melting or discoloring because of the high temperature after long operation of the equipment.

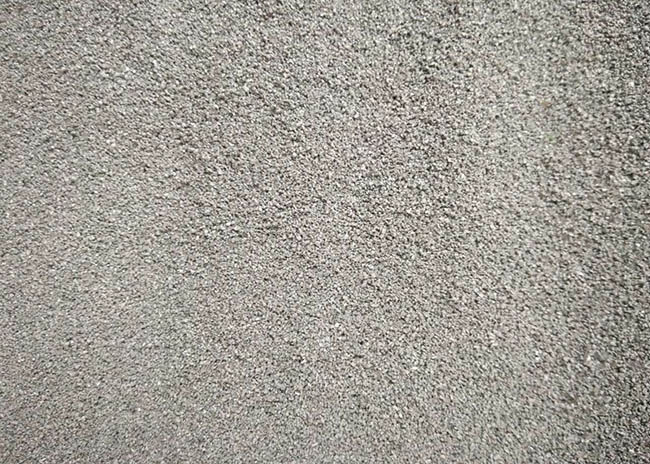

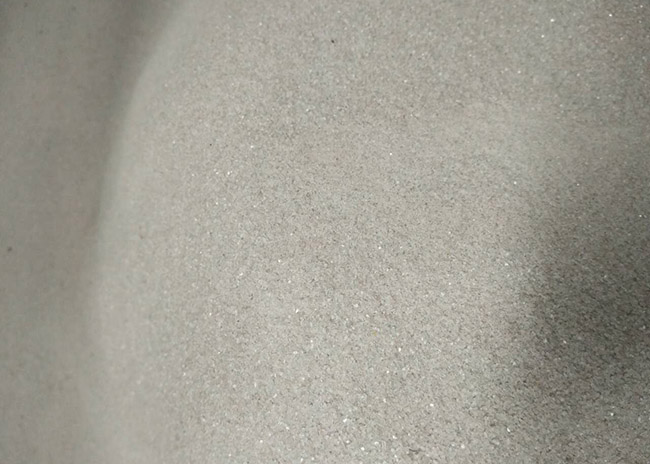

- Physical crushing, grinding and electrostatic separation method to sort the aluminum and plastic. It is environmentally and friendly separation method which replaced the original chemical pharmacy aluminum-plastic separation.

- The entire production line is equipped with pulse dust collector, thus purifying the work space.

- The highest separating rate of aluminum and plastic can reach more than 99.9%.

- Equipment can be customized according to customers' capacity requirement.

|

Model |

Power (kw) |

separating rate (%) |

Dust Collection efficiency (%) |

Output (kg/h) |

Overall dimension (mm) |

Weight (kg) |

|

APS-300 |

70 |

≥99% |

≥99.5% |

200-300 |

7500*6000*4200 |

6500 |

|

APS-600 |

115 |

500-600 |

9500*7500*4200 |

7800 |

||

|

APS-800 |

215 |

700-800 |

11500*8000*4200 |

12800 |

-

factory low price Otr Tire Cutter - Plastic gr...

-

High Performance Scrap Metal Shredder - Waste ...

-

Good quality Pet Bottle Recycling Washing Plant...

-

2018 Latest Design Tyre Crusher Machine - Wast...

-

Factory wholesale Coax Stripper - Integrated-t...

-

2018 wholesale price Waste Oil Recycling To Die...

+

+ +

+ +

+ +

+ +

+ +

+