2T/5 T/8T/10T/12T Per Batch Tire/Rubber/Plastic Pyrolysis Plant

Customer's requirement: Fast installation and moveable parts

Our solutions:

(1)Assemble the reactor,cover and the base together in our factory.For easily installation and shipment. See below pictures.

(2)Assemble the steel water tank and pipes in our factory,instead of concrete water pond and pipes assemble in your worksite.For easily installation and moveable.

See below pictures.

Features and working principle

- Tire Loading method :This machine choose automatic hydraulic feeder load material. The automatic hydraulic feeder can push full tire inside automatically.and load extra more 2mt-3mt tire than conveyor belt.

- Heating mode :This pyrolysis plant we can choose waste tire oil gas heating , tire oil heating,heavy oil heating, natural gas heating ,wood heating ,coal heating etc . After machine heating 2-3hours, it will start produce tire oil and mean while the produced waste gas which can be recycled to heat the reactor itself and save power.

- Cooling method : This pyrolysis machine we use the water pond&cooling tower cooling system.Pond and Pipes are fixed together,easily install and move. The light pyrolysis oil gas go inside the coiled pipes and be cold by water outside pipes and go inside light oil tank , the heavy oil gas go inside damper tank . We provide 16 units pipes and make sure enough heat exchange area and improve oil gas yield rate .

- Final Products(Eg,waste tire): Oil yield Rate: 42-45%; Carbon black:30%; Waste steel:15%; waste oil gas: 10%.

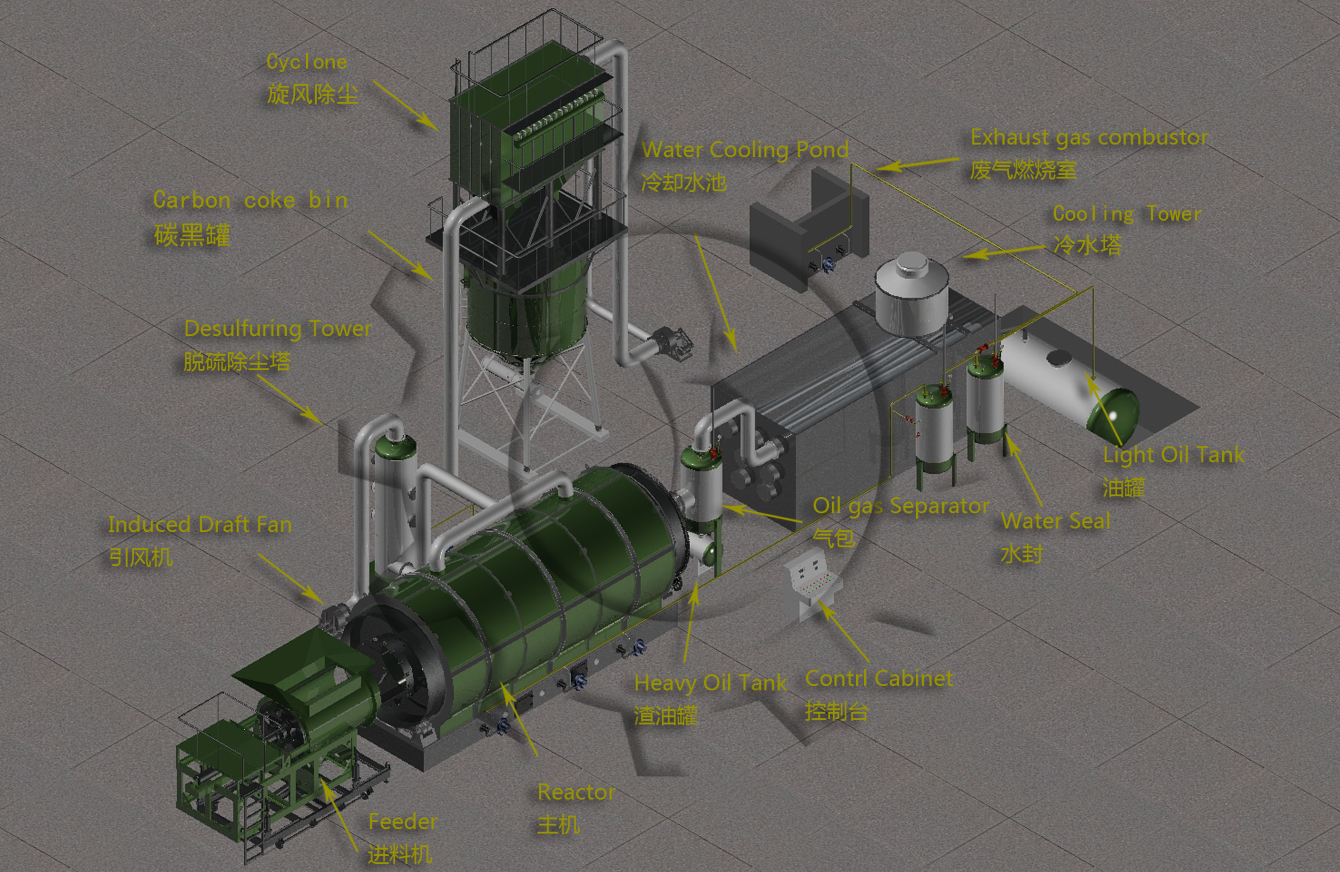

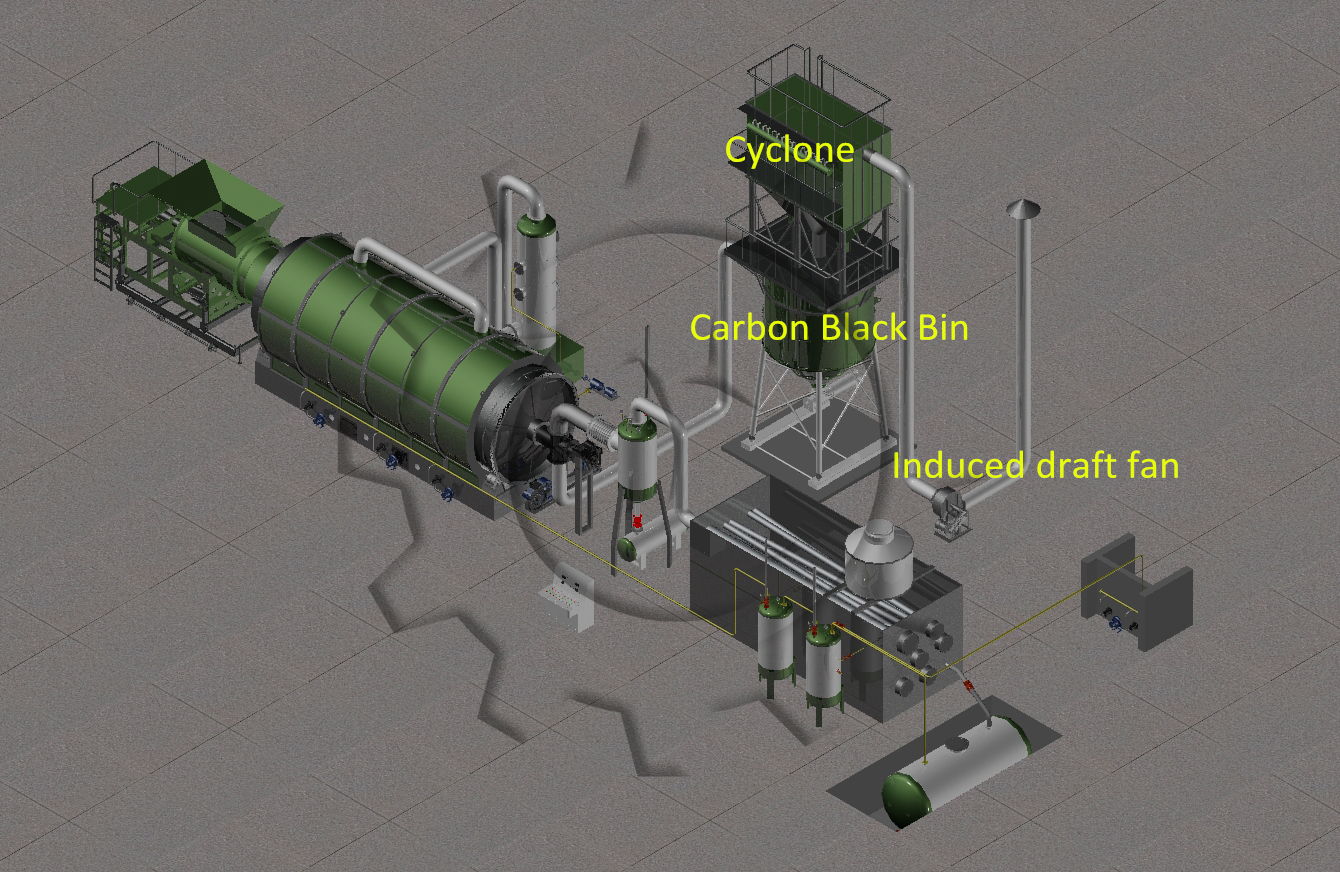

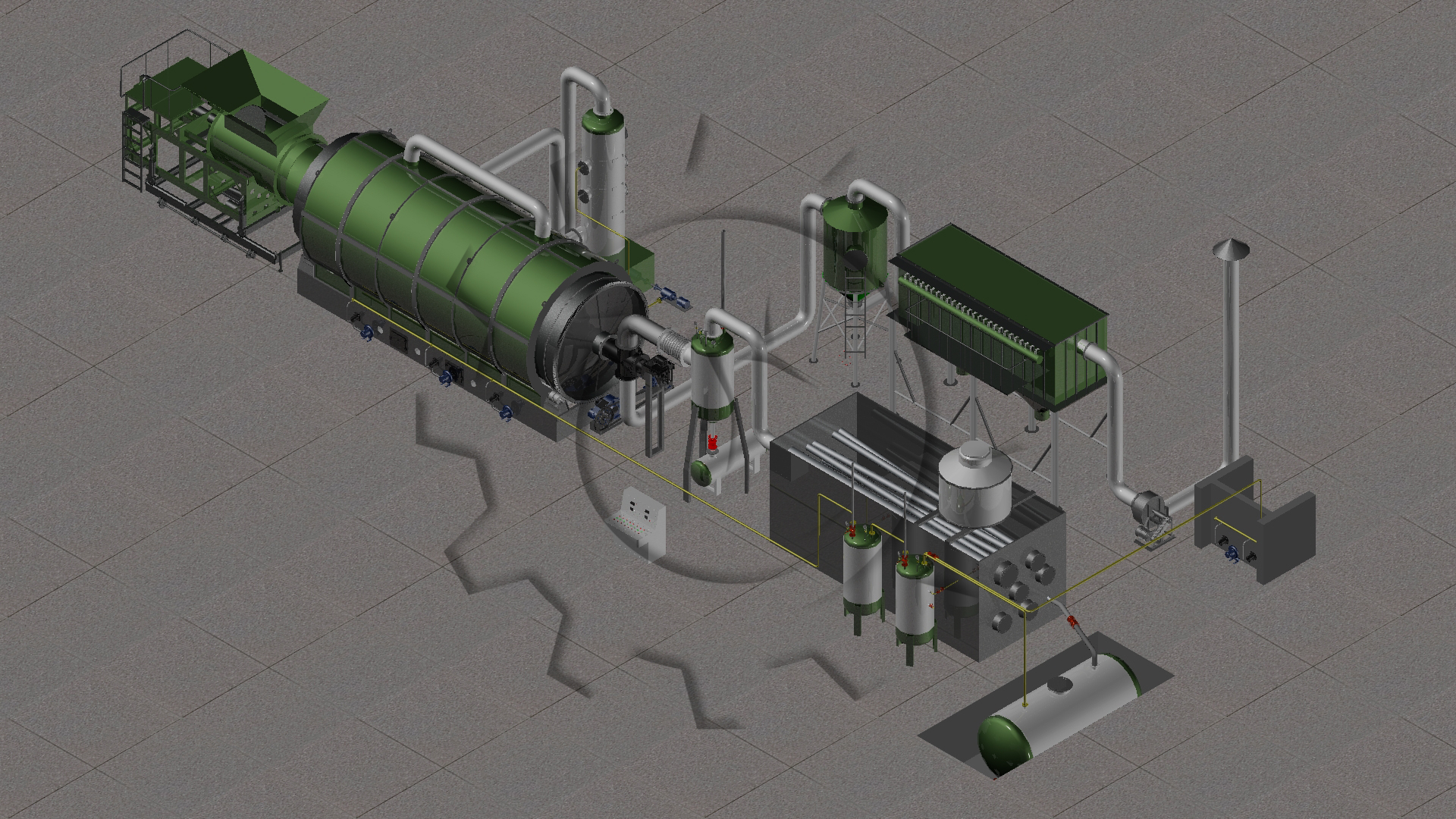

Layout in 3D for your reference(Can design the layout based on your worksite):

The total plant is only need to be placed on a flat concrete floor, not need of bolts to fix to the ground.

Post time: Mar-04-2021