We will devote ourselves to supplying our esteemed prospects while using the most enthusiastically considerate providers for OEM/ODM Supplier China Waste Tire and Plastic Pyrolysis Plant for Fuel Oil, As an experienced group we also accept customized orders. The main goal of our company is to build up a satisfying memory for all customers, and establish a long-term win-win business relationship.

We will devote ourselves to supplying our esteemed prospects while using the most enthusiastically considerate providers for China Tyre Pyrolysis Plant, Rubber Pyrolysis Plant, We integrate all our advantages to continuously innovate, improve and optimize our industrial structure and product performance. We are going to always believe in and work on it. Welcome to join us to promote green light, together we are going to make a better Future!

1.Raw Material of Pyrolysis Machine

|

NO.

|

Name

|

Photos

|

|

1

|

Many Kinds of Waste Plastic

PE>70%,PVC <20%.

More PE, Higher Oil Yield Rate |

|

|

2

|

Waste Tire

|

|

|

3

|

Waste Rubber

|

|

|

4

|

Waste Cable Leather

|

|

|

5

|

Waste shoe sole

|

|

|

6

|

Many kinds of oil sludge

|

|

|

7

|

Waste Acrylic

|

|

|

8

|

Waste leather

|

|

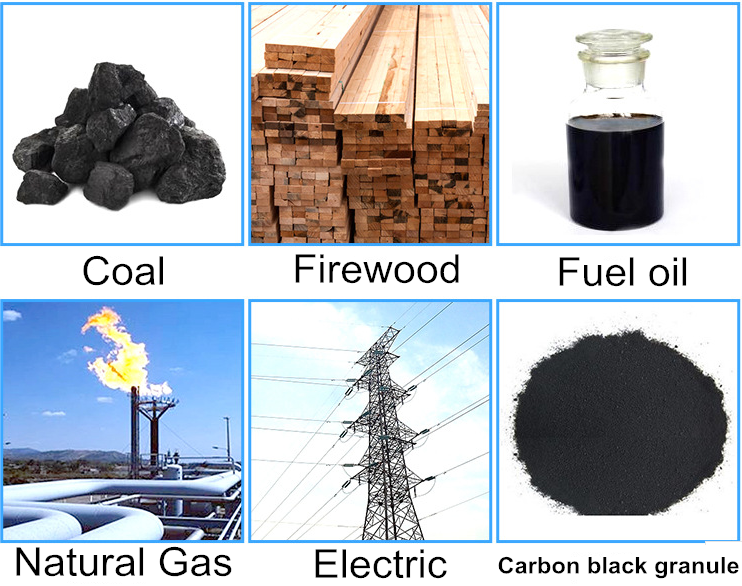

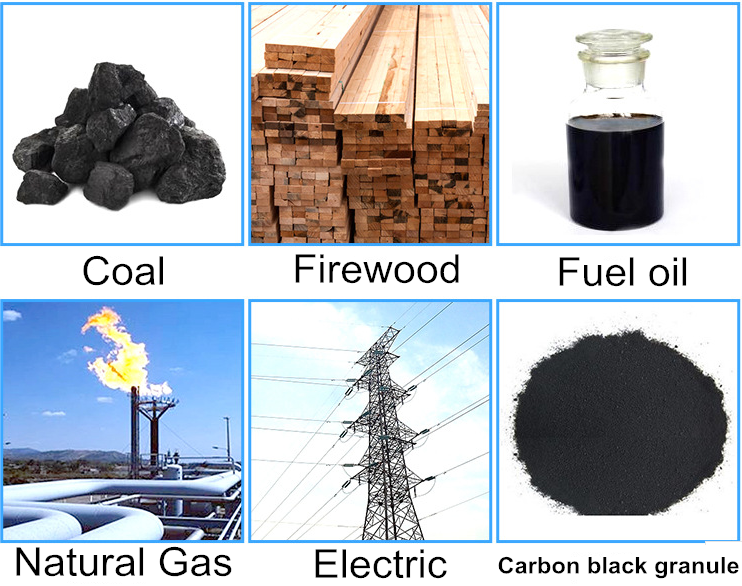

2.The Fuel The Machine Can Use

|

NO.

|

1

|

2

|

3

|

4

|

5

|

6

|

|

Fuel

|

Coal

|

Firewood

|

Oil(Fuel/Tire/

Heavy oil etc)

|

Natural Gas

|

Electricity

|

Carbon black pellet

|

|

Note

|

/

|

/

|

Heavy oil burner

|

Natural gas burners

|

Electric heating system

|

By the carbon black pellet machine

|

3. End product Rate and usage

|

Raw Materials

|

End product rate

|

|

Furnace Oil

|

Carbon black

|

Steel

|

Waste Gas

|

|

Waste tire/rubber

|

Truck tires

|

45%--50%

|

25%-30%

|

10%

|

10%-15%

|

|

Car tires

|

40%-45%

|

30%-35%

|

10%

|

10%-15%

|

|

Bicycles and motorcycle tires

|

30%--35%

|

35%-40%

|

10%

|

15%-25%

|

|

Waste plastic

|

Fishing net,

Safety net, farm-oriented film

|

45%--50%

|

30%-40%

|

|

15%-25%

|

|

Convenient bags , weave bags

|

40%

|

40%

|

|

20%

|

|

Off-cut of recycled paper mill

|

20%--30%

|

45%-55%

|

|

25%

|

|

No

|

End product

|

Usage

|

Picture

|

|

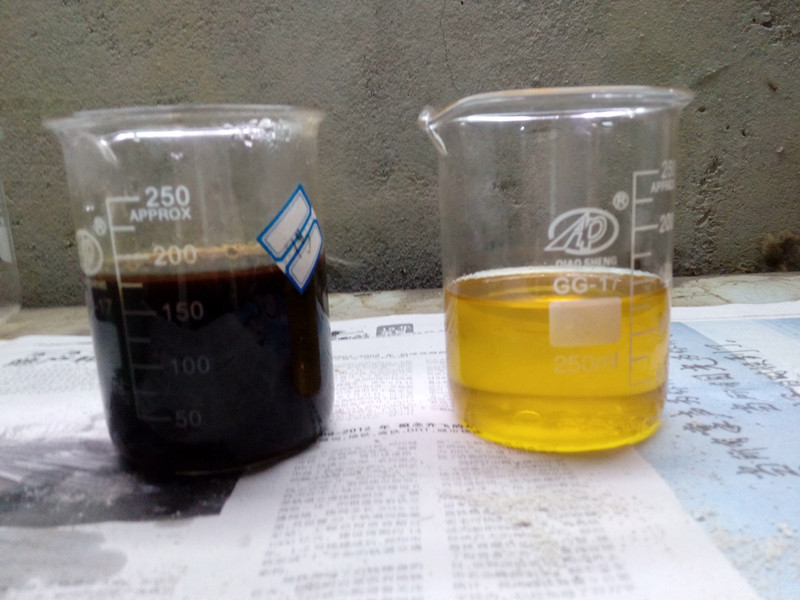

1

|

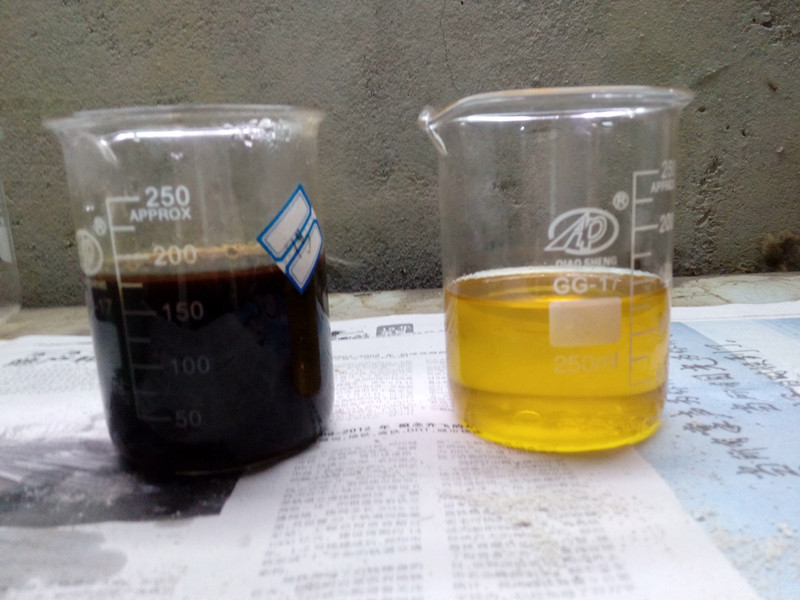

Tire oil

|

* For sale.* Distillating to Diesel and Gasoline.* Used as fuel. |

|

|

2

|

carbon black

|

* For sale.* Refine to Fine carbon black.* Produce Carbon Black Pellet |

|

|

3

|

Waste Steel wire

|

*For sale.*Packaging to steel block for easy transportation and storage. |

|

|

4

|

Oil gas

|

* As fuel* Excess exhaust gas can be stored in the storage system. |

|

5.Model And Capacity

|

NO.

|

Model

|

Reactor size

|

Capacity

|

Note

|

|

1

|

ST-2200*6000

|

2200*6000mm

|

5-6 Ton/batch

|

2 days 3 batches

|

|

2

|

ST-2200*6600

|

2200*6600mm

|

|

3

|

ST-2400*6000

|

2400*6000mm

|

6-7 Ton/batch

|

2 days 3 batches

|

|

4

|

ST-2400*6600

|

2400*6600mm

|

|

5

|

ST-2600*6000

|

2600*6000mm

|

8-10Ton /batch

|

1 day 1 batch

|

|

6

|

ST-2600*6600

|

2600*6600mm

|

|

7

|

ST-2800*6000

|

2800*6000mm

|

10 Ton/batch

|

1 day 1 batch

|

|

8

|

ST-2800*6600

|

2800*6600mm

|

12 Ton/batch

|

1 day 1 batch

|

|

9

|

ST-2800*8100

|

2800*8100mm

|

15Ton/batch

|

1day 1batch

|

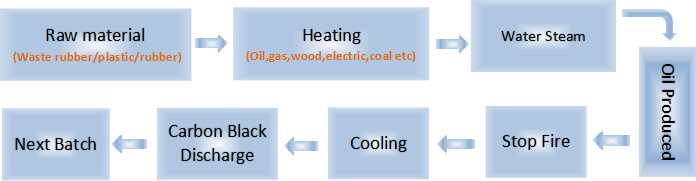

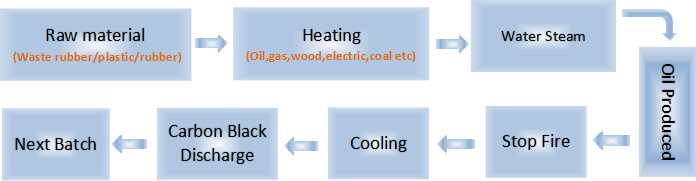

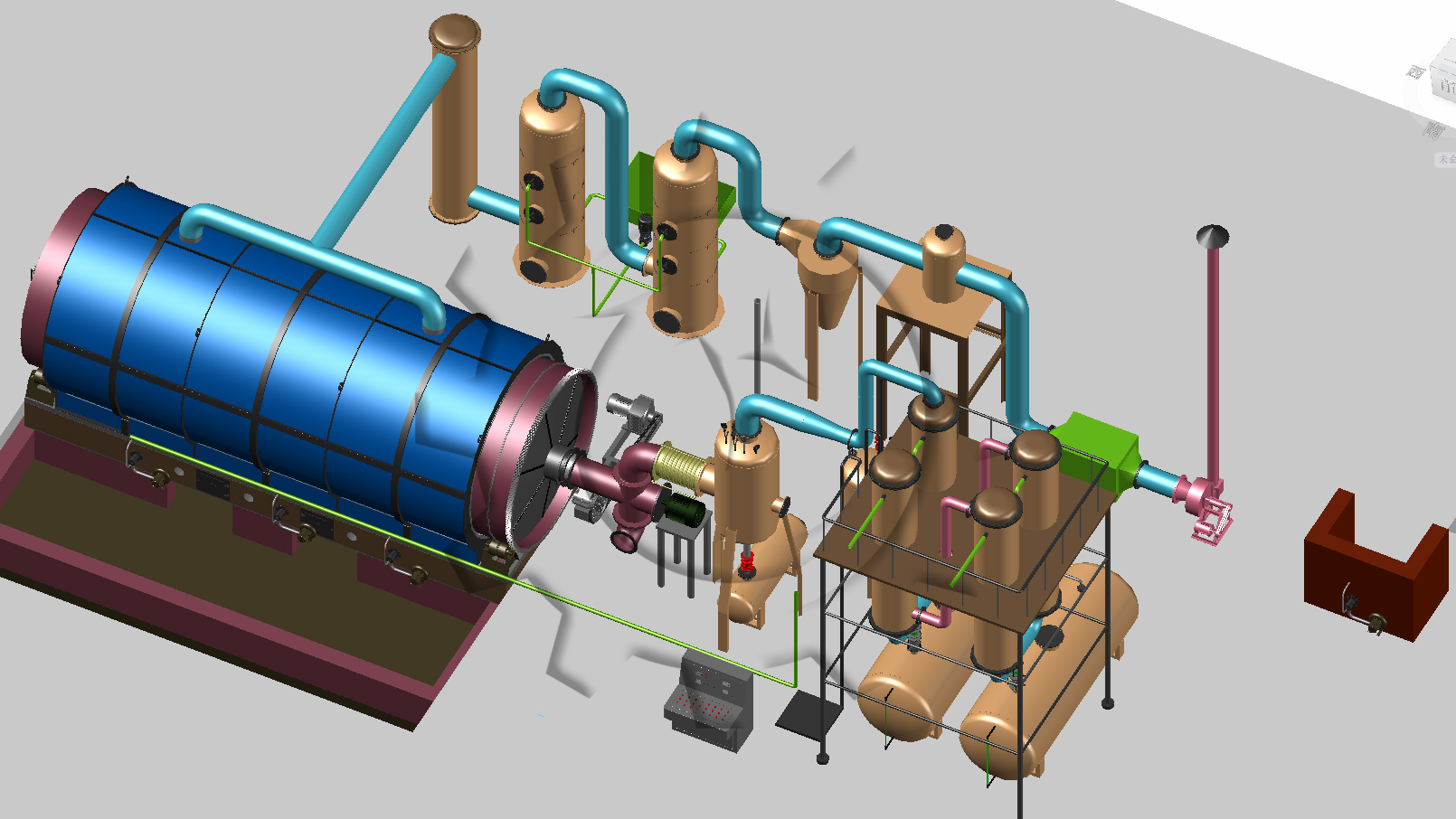

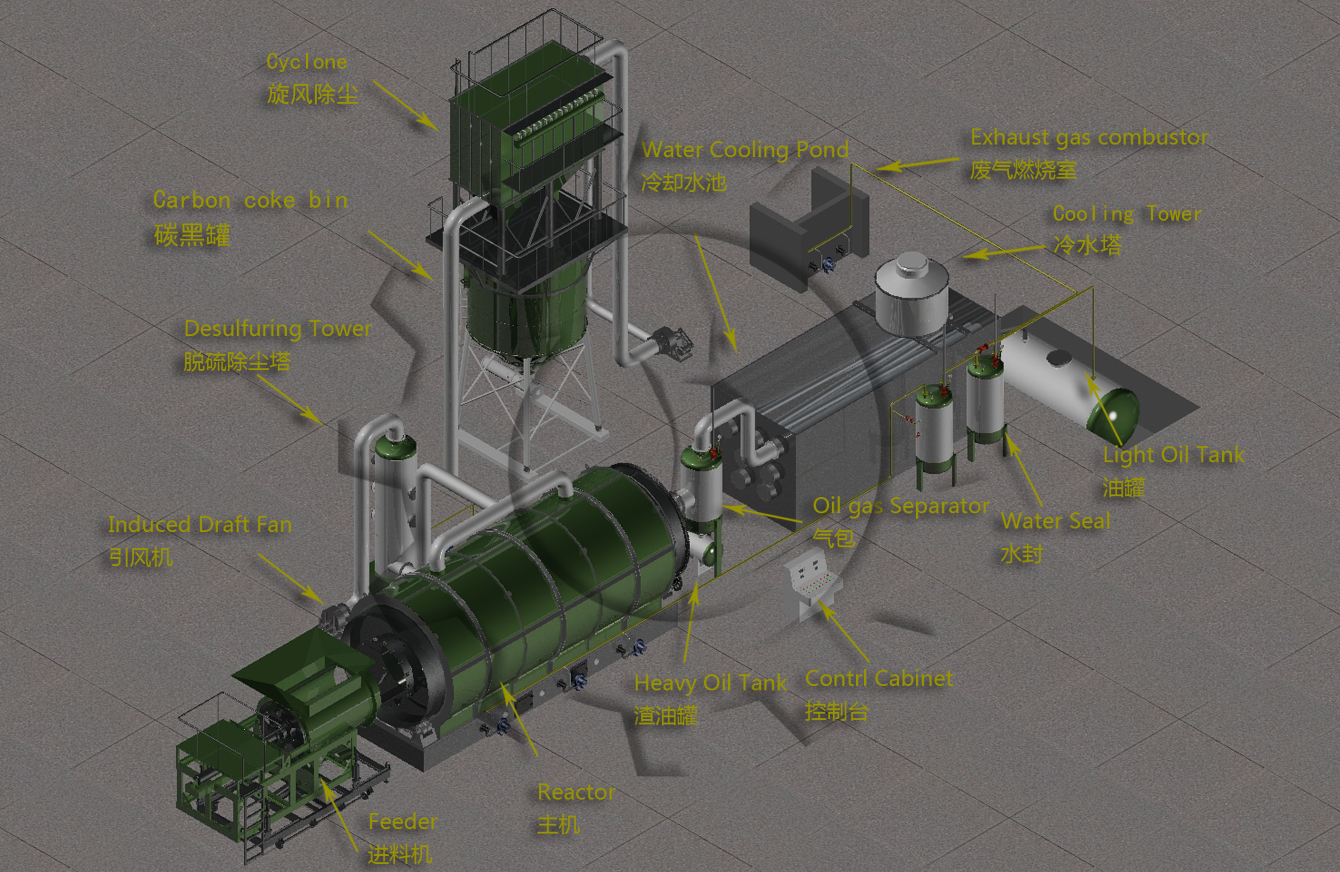

6.Working Principle

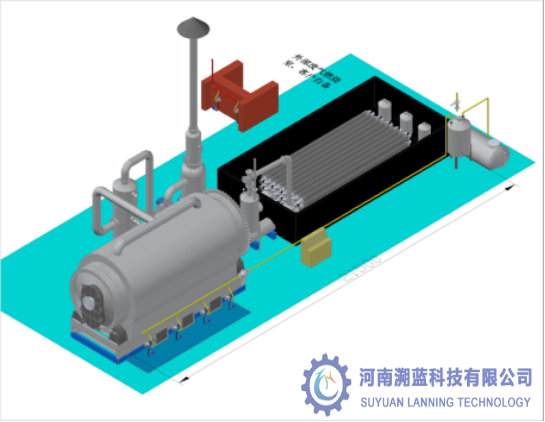

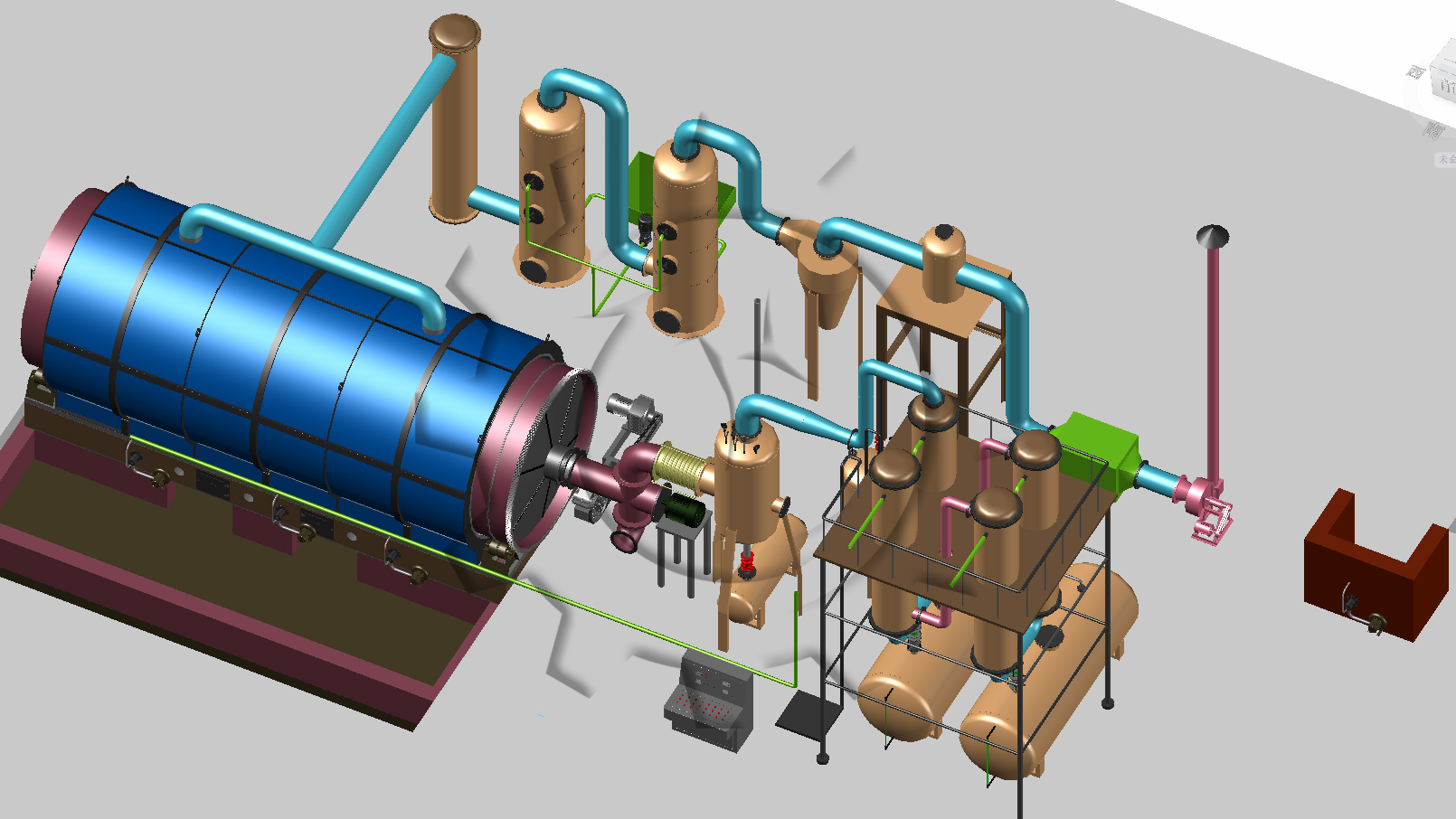

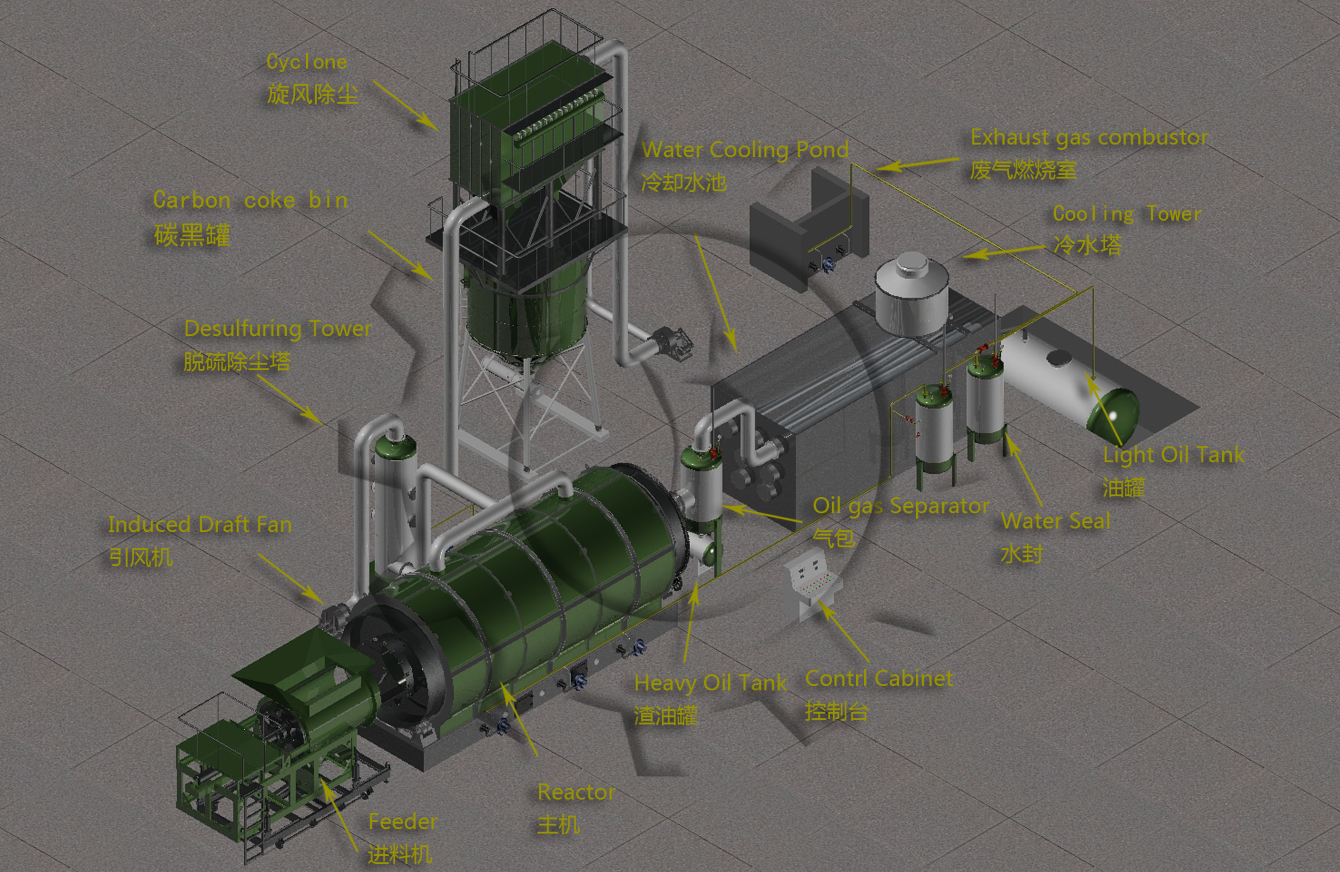

7.Configuration 5-15tons

The configuration and capacity can be adjusted according to customer’s requirement.

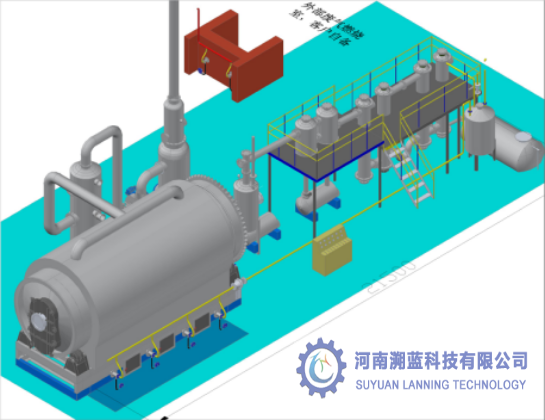

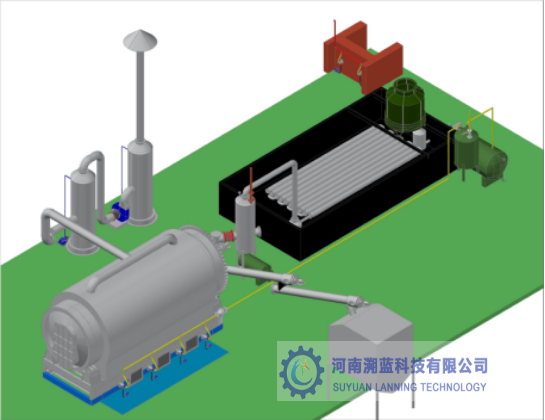

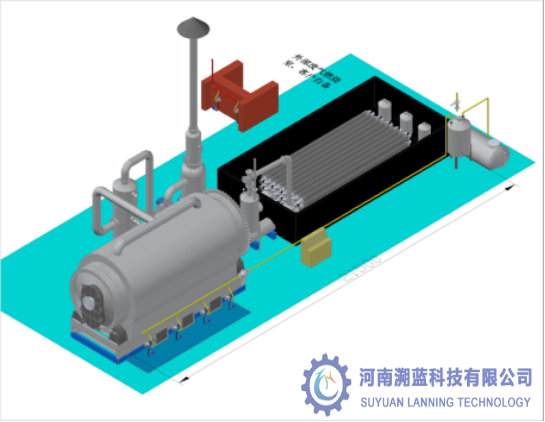

(1)Pyrolysis Plant With Water Pool Cooling System/Front Discharge

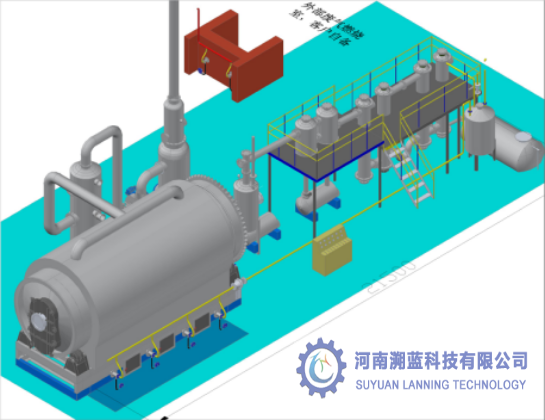

(2)Pyrolysis Plant with Vertical condenser cooling system/Front Discharge

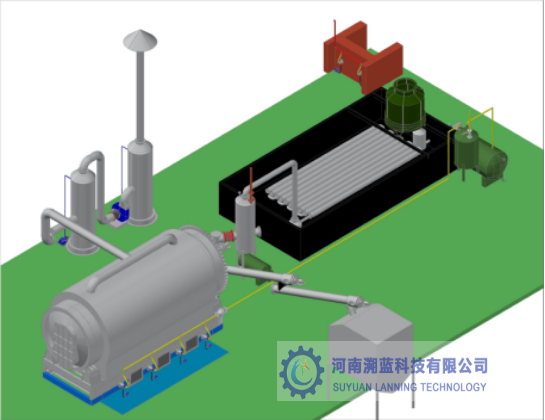

(3)Pyrolysis Plant with Water Pool Cooling System/Rear discharge

(4)Pyrolysis Plant with condenser cooling system/rear discharge

(5) Pyrolysis Plant with Water Pool Cooling System/Rear negative pressure discharging system

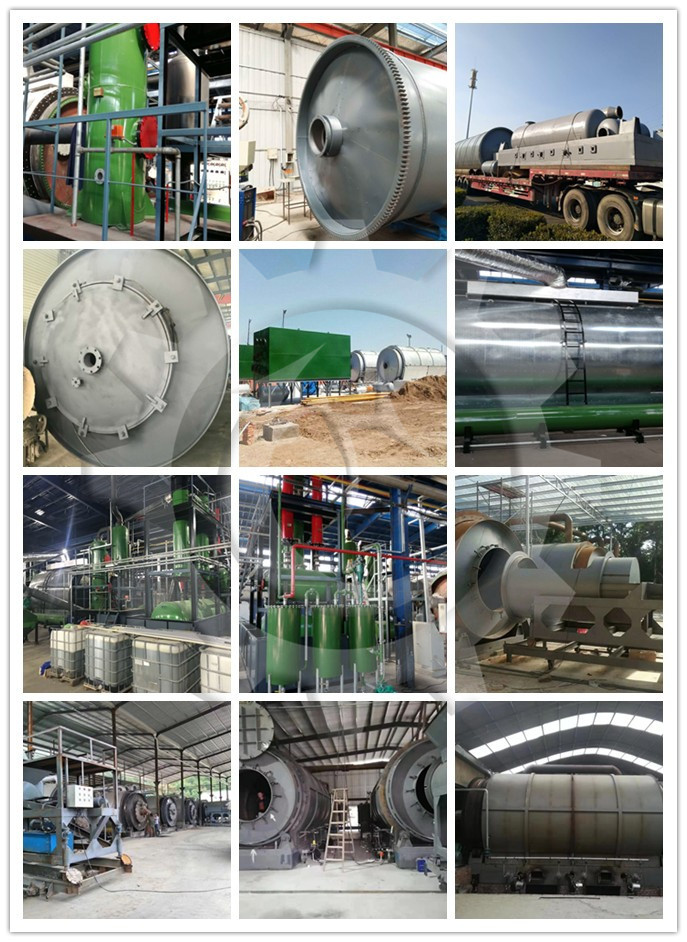

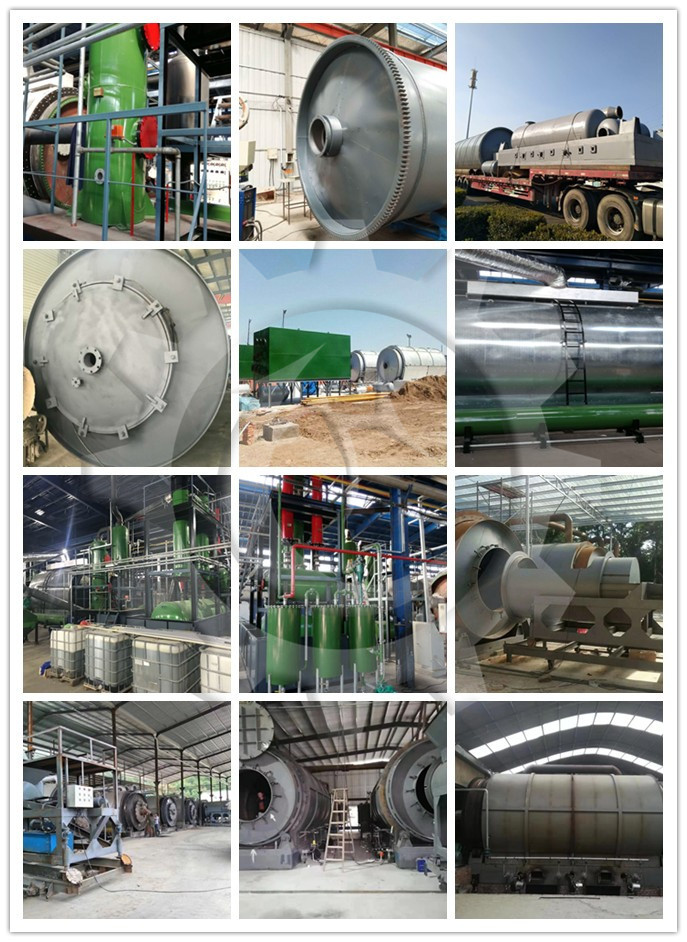

8.Pictures

(1)Details

(2)Shipment

(3)Worksite

Previous: Hot-selling China Copper-Clad Laminate Printed Circuit Board Recycling PCB Scrap Crushing Machine

Next: OEM Supply China Environmental Protection Waste Plastic/Tyre Pyrolysis Plant

+

+ +

+ +

+ +

+