Semi-mobile 5T per batch tire plastic rubber Pyrolysis Plant

We are also specializing in improving the things management and QC method in order that we could retain terrific edge inside the fiercely-competitive small business for Semi-mobile 5T per batch tire plastic rubber Pyrolysis Plant, Should you pursuit the Hi-quality, Hi-stable, Competitive price tag sections, enterprise name is your very best choice!

We are also specializing in improving the things management and QC method in order that we could retain terrific edge inside the fiercely-competitive small business for China Pyrolysis Plant, Plastic Recycling, We adhere to client 1st, top quality 1st, continuous improvement, mutual advantage and win-win principles. When cooperation together with the customer, we deliver shoppers with the highest high-quality of service. Established good business relations using the Zimbabwe buyer inside the business, we've got established own brand and reputation. At the identical time, wholeheartedly welcome new and old prospects to our company to go to and negotiate small business.

1.Raw Material of Pyrolysis Machine

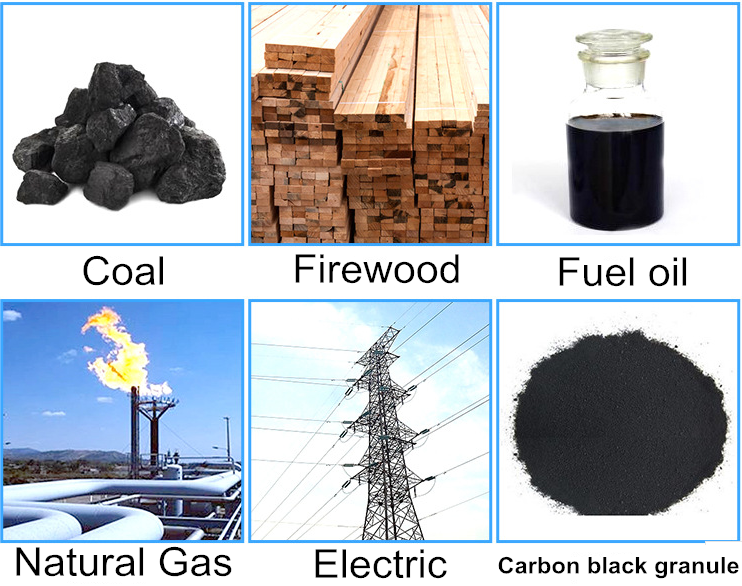

2.The Fuel The Machine Can Use

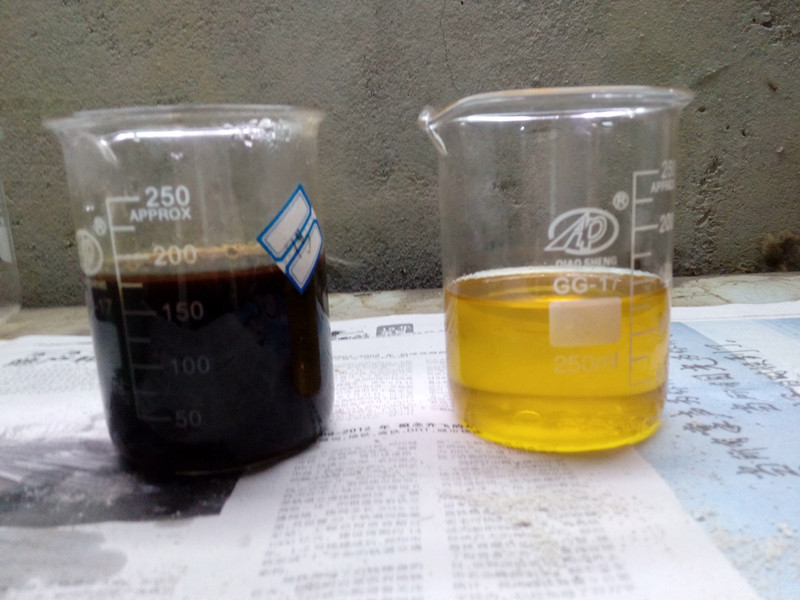

3. End product Rate and usage

5.Model And Capacity

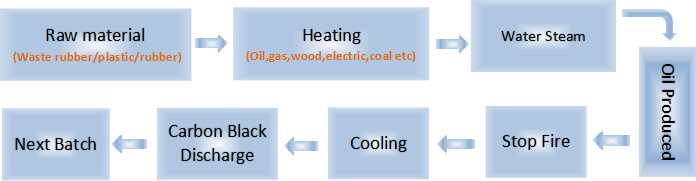

6.Working Principle

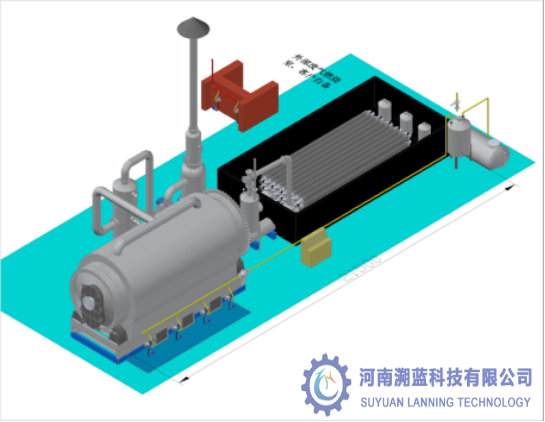

7.Configuration 5-15tons

The configuration and capacity can be adjusted according to customer’s requirement.

(1)Pyrolysis Plant With Water Pool Cooling System/Front Discharge

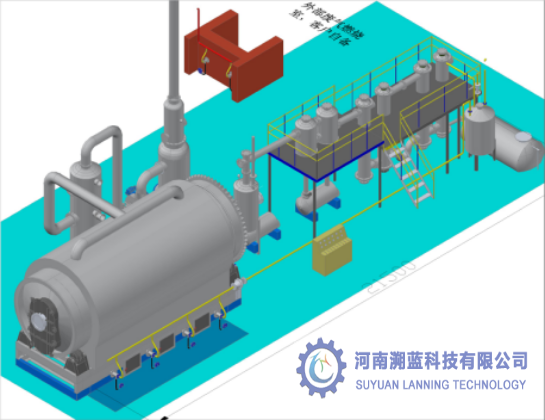

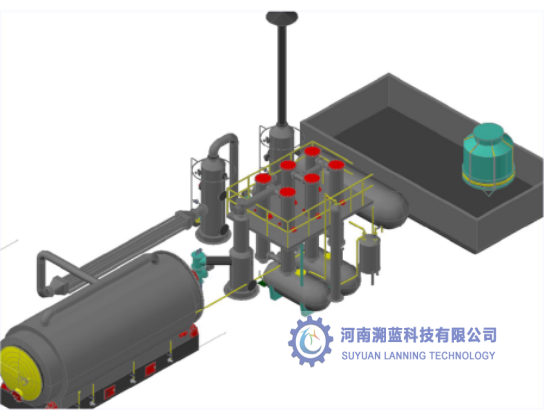

(2)Pyrolysis Plant with Vertical condenser cooling system/Front Discharge

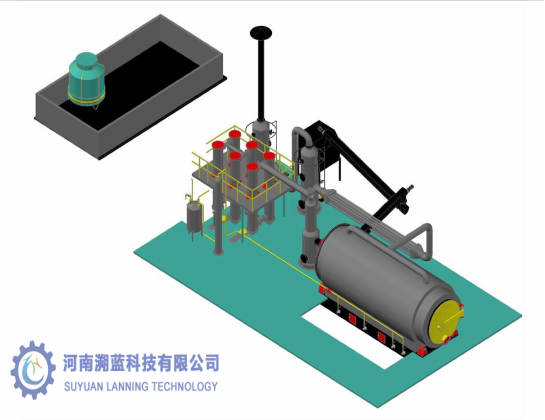

(3)Pyrolysis Plant with condenser cooling system/rear discharge

(4)Pyrolysis Plant with condenser cooling system/high temperature discharge

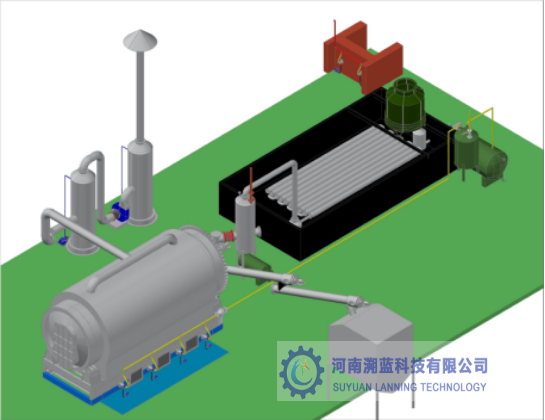

(5) Pyrolysis Plant with Water Pool Cooling System/high temperature discharge

8.Shipment and Customer's Worksite

+

+ +

+ +

+ +

+