Taayirka to Powder warshad soo saarta

Macluumaadka Alaabta

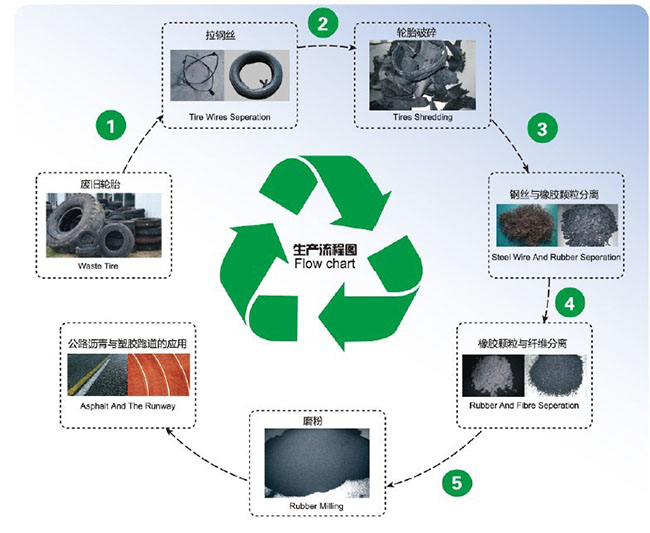

Khadka Dib-u-warshadaynta Taayirka Qashinku waxa uu qaadanayaa habka dib-u-warshadaynta jirka waxana uu ku habboon yahay in la horumariyo oo la soo saaro Taayirka Qashinka ah ee Rabadhka Granules Plant, badiyaa waxa uu ku habboon yahay shiididda, taayirka siliga, taayirka siliga birta (taayirka radial), iyo dhammaan noocyada alaabta caagga ah ee qashinka ah. ama walxo hadhaaga ah, oo ka dhigaya budada, oo gaadha ganaaxa loo baahan yahay (mesh).Khadkaan dib-u-warshadaynta taayirka qashinka ah oo ku socda heerkul caadi ah, looma baahna in lagu daro kiimikooyin kale, wax wasakh ah kuma laha deegaanka.Tani waa habka ugu wanaagsan ee dib u warshadaynta taayirada qashinka ah.Waxaad u hirgelin kartaa xalka la-qabsiga macaamiisha.

Ku haboonAlaabta ceeriin

Waxaa inta badan lagu dabaqaa noocyada kala duwan ee taayirada qashinka, tuubada taayirrada qashinka, suunka qashinka, tuubada caagga ah, iyo kabaha caagga ah ee qashinka ah.

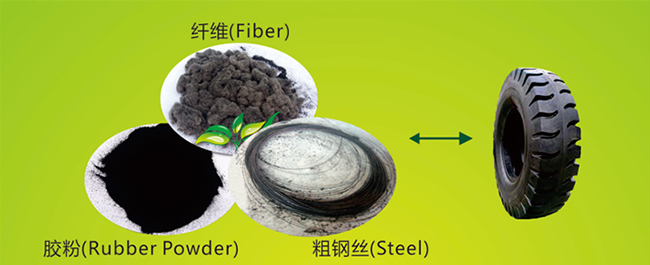

Alaabooyinka u dambeeya

Budada caagga ah, Fiber iyo Silig bir ah.

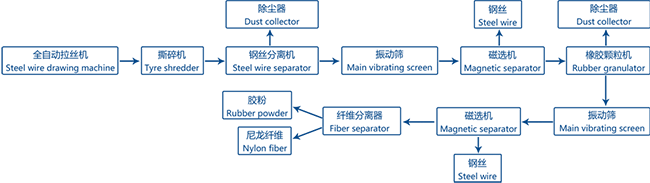

Ugu weynQalabka

Geedka oo dhan oo ay ku jiraan Soosaarayaasha Taayirka Haydarooliga, Gooyaha Taayirka, Taayirka Qashinka/Calabka Shredder, Kala-soocida Siliga Birta, Granulator-ka caagga ah, Kala-soocida Magnetic, Kala-duwayaasha Fiber.Naqshadaynta guud waa mid macquul ah, heer sare oo otomaatig ah, fududahay in la isticmaalo lana ilaaliyo.

Qaabka Qalabka:

Jaantuska socodka

+

+ +

+ +

+ +

+ +

+ +

+