Se arola lintho tsa polasetiki tse tsoakiloeng

Semela se arolang sa polasetiki se tsoakiloeng

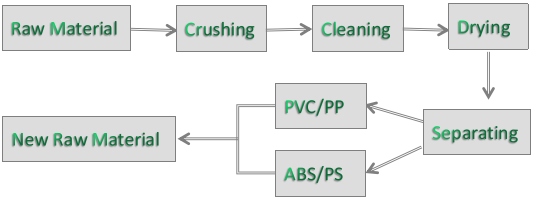

Semela se arohaneng sa polasetiki se kopantsoeng se sebelisoa haholo ho arola mefuta eohle ea polasetiki e robehileng ea lisebelisoa tsa ntlo, likoloi le likoloi tsa motlakase, lintho tsa ho bapala tsa motlakase le lipolasetiki tse ling tse tsoakiloeng tsa lisebelisoa tse khethehileng kamora ho tlosoa ha tšepe, joalo ka: ABS / PS, PMM / PC, PET. /PVC,PP/PE,PA/ABS.Thepa ea karohano ea polasetiki e amohela mokhoa o phahameng oa ho arohana ha motlakase oa motlakase, o na le likarolo tsa ts'ebetso e phahameng le phello e ntle ea karohano, ke lisebelisoa tse ntle ka ho fetisisa tsa karohano ea polasetiki.

Kamora ho sila, ho hlatsoa, lisebelisoa tsa hau tse fapaneng tsa polasetiki li tla kena mochining oa rona oa ho omisa ho omisoa, ebe ka jenereithara ea rona ea motlakase ho ea ho motlakase, mme ho latela thepa e fapaneng ea motlakase bakeng sa polasetiki e fapaneng, mochini oa rona oa ho arola polasetiki o ka arola mefuta e fapaneng ea lisebelisoa. lisebelisoa tsa polasetiki.

Sebopeho:

- Theknoloji e tsoetseng pele .Ke sete e feletseng ea mohala oa kopano.e laoloang ke PLC automation control cabinet.Lihokelo tsa lipalangoang tse mahareng tsa sesebelisoa ka seng li boloka mosebetsi mme li ka sebetsoa habonolo.

2. Bohloeki bo phahameng bo arohaneng le bokhabane bo phahameng ka electrostatic.Ho hlopha bohloeki ho ka fihla ho feta 99%.

3. Lerata le tlaase le ts'ebetso e bonolo.

4. Pulse lerōle tsamaiso ea ho qoba tšilafalo.

5. Moralo o utloahalang o etsa hore tlhokomelo e be bonolo.

Litekanyetso tsa tekheniki: