Waste Radiator Crushing&Recycling Line

Raw waste:Various kind of warped radiator

Application:

It is suitable for recycling the waste radiators from Air conditioning, automobile,etc... sorting out the copper, iron, aluminum.

Crushed Radiator mixture before separating:

Final products after separating:

Technology Introduction:

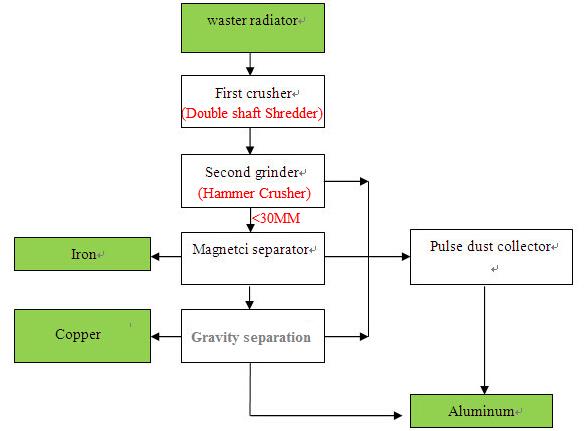

Put the material to the first crusher for the primary crushing and the crushed material conveying by the conveyor to the second grinder. The materials in the grinder will be crushed into the length of the 3cm. Then the materials went through magnetic separation to separate iron, then Gravity separation to separate the copper and aluminum. The whole production line is controlled by negative pressure and equipped with the pulse dust catcher to solve the dust problem.

Flow chart:

Advantages:

1. Compared to Europe processing technology, our process has lower metal loss, we try to reduce the number of times materials being crushed, thereby reducing the generation of metal powder to improve recycling efficiency.

2. The first crusher designed by double roller and have the advantage of low noise and large torque,capable of crushing radiator in big size.

3. The blades of first crusher is made of alloy steel, with the special process makes the durable life longer than one year.

4. Using two times gravity separation, which improve the sorting accuracy.Sorting out of copper, aluminum, iron purity > 99%

5. With closed processing and dust collection system, which to effectively control the dust overflow.

+

+ +

+ +

+ +

+ +

+ +

+