Wholesale Price China Plastic Recycling Line Equipment - Dc Motor Recycling Machine Electric And Automatic Motor Stator Copper Wire Recycling/pulling/dismentling Machine – Suyuan Lanning

To create more benefit for buyers is our business philosophy; shopper growing is our working chase for Dc Motor Recycling Machine Electric And Automatic Motor Stator Copper Wire Recycling/pulling/dismentling Machine, Welcome all nice consumers communicate information of items and ideas with us!!

To create more benefit for buyers is our business philosophy; shopper growing is our working chase for Motor Recycling Machine, Used Motor Oil Recycling Machines, Waste Motor Oil Recycling Machine, Our focus on product quality, innovation, technology and customer service has made us one of undisputed leaders worldwide in the field. Bearing the concept of "Quality First, Customer Paramount, Sincerity and Innovation" in our mind, We've achieved great progress in the past years. Clients are welcomed to buy our standard products, or send us requests. You are going to be impressed by our quality and price. Make sure you contact us now!

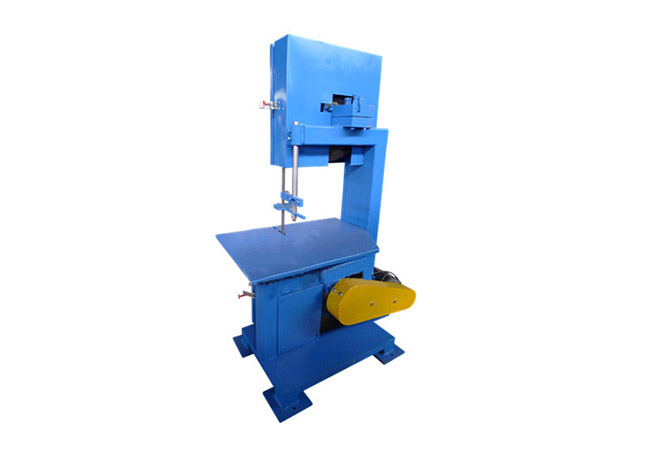

Motor Crushing Recycling Production Line

Applicable Scope:

Motor stator、Motor rotor、Small transformer、Valve、Water meter 、Brass plastic mixture、 Other copper, iron and plastic mixture。

Technology Introduction:

Motor crushing recycling production line is mainly used for scrap metal recycling of copper, iron and plastic. We crush the material first, and separate the copper, iron, plastic via magnetic and gravity separation system.

Advantages:

1. The equipment layout is reasonable, can handle a variety of materials, high economic efficiency with large capacity.

2. Hammer crusher with high-speed, the bulk of high strength materials can be fully and rapidly broken.

3. Strong processing capability, stable operation

4. High degree of automation, uniform feeding with coordination

5. The blades are made of special tool steel, which is more durable and sturdy

6. Multi-channel magnetic separation is used for Iron removal system, with high separation efficiency

7. With cooling system, to make sure the equipment can withstand high load operation

8. Effective control of dust by using dust removal equipment

Before Processing:

+

+ +

+ +

+ +

+